| THE INDUSTRIAL RAILWAY RECORD |

© DECEMBER 1965 |

THE NORTH SURREY JOINT

SEWAGE BOARD

C. G. DOWN

In 1912 the Surbiton Borough Council awarded the contract for the construction of their new sewage treatment works to Dick, Kerr & Co. Ltd. of Surbiton, and Isle & Company. The new works was to be situated between the London & South Western Railway main line near to the present Berrylands station and Lower Marsh Lane which ran across the fields and under the railway. Partial treatment of sewage was begun on 19th July 1913, when a party of eighty local dignitaries toured the works, afterwards adjourning to a nearby public house to hear a paper on the project. The new works was to replace existing ones at Hook, Southborough and Tolworth, this last being a source of strong local complaint. The cost of the new installation was at least £70,000, but it could cope with about 30,000 people, 12,000 more than the population of the Borough. A refuse destructor which had also been installed provided heat to generate steam for the machinery.

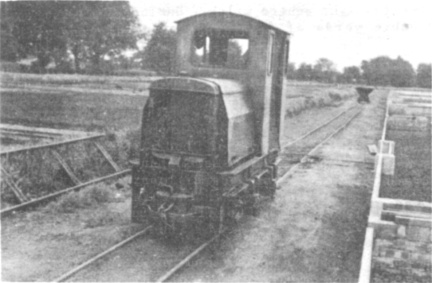

In 1939 a modernised process for sewage treatment was introduced, which remains in use up to this day. In connection with this, sludge drying beds were constructed, and a 2' 0" gauge railway laid down to serve them. The railway commences near Berrylands station and runs between the drying beds, throwing off branches to storage sheds and the grit separation plant. The line then turns at right angles across a private road and runs alongside it to a point where the grit is tipped. At the time of writing, the line runs about twenty Hudson skips, and these are hauled by a four-wheel diesel locomotive painted light green (Hibberd 2201 new in 1939). Sanding gear is fitted to cope with the gradient up to the grit tip.

A short distance away from this disposal works is another which was built around 1900 by the Maiden & Coombe Borough Council. They, too, were busy here during 1913. On January 18th a sum of £2,500 was authorised for the installation of a dust destructor at the rubbish tip which, as at the Surbiton works, shares the sewage disposal site. A sum of £5,300 was also authorised for extensions to the sewage works itself, while on March 15th the Council was empowered to borrow £6,897 of the money required for these improvements.

In 1939, too, the Maiden works introduced a short 2' 0" gauge railway to serve the newly installed sludge drying beds. To work the line a two cylinder diesel locomotive painted dark green was obtained (Hunslet 1962 new in 1939). The controls consist of clutch and throttle, with the gear column in front of a vertically mounted brake wheel. The track at the works can be described as short, flat and devious, with no interesting features.

In between these two disposal works lay a large tract of land, and it was here that in 1931 the Hogsmill Valley Joint Sewage Board proposed to establish another sewage works. Due to local objections and the War, construction of the works was delayed, but began in 1953. In 1932 the cost of the works had been estimated at £340,000 but, when the works was officially opened on 7th October 1957, some £2,000,000 had been spent. Of the three works this is, of course, the most advanced, and a description of the process used to purify the sewage here may be of interest.

Hibberd 2201 at Surbiton Works

on 15th August 1963. (C. G. Down)

At present, the works deals with a Dry Weather Flow of sewage of 7½ million gallons per day, the other works at Malden and Surbiton dealing with 2½ million gallons between them. Sewage is discharged into constant velocity (one ft. per sec.) grit channels where the grit settles, is dredged, and then passed to skips for disposal. The sewage then passes via four comminutor units to four primary settling tanks. After this comes the purification plant where air is bubbled through the sewage to promote bacterial action. Purified sewage passes to secondary settling tanks, and the purified effluent is removed from these to the river Hogsmill. The latter consists of eight parts effluent to one part river water, but sticklebacks seem happy enough in it! The purified sludge is pumped to primary and secondary digestion tanks. From the primary tanks a great deal of gas is collected which is burned at the power house to provide steam to heat the digestion tanks. The resultant condensate cools the diesel generators, and the hot water is vaporised to heat the digestion tanks again. After chemical treatment the sludge is piped to one of about twenty-two drying beds, each served by an extensive 2‘ 0" gauge railway system. The fort or so skips are hauled by a diesel locomotive (Hunslet 4857 new in 1957 painted green, cream and red.

In 1961 the three works were amalgamated and the North Surrey Joint Sewage Board formed. The Board soon put two bridges across the river Hogsmill, which both carry rail tracks. One set of rails connects up with the Maiden system. Another four-wheel diesel, (Hunslet 6018), identical to the other, was supplied new in 1961, and a two road shed built to house them. In the winter one of the engines is usually stored as the drying beds then take longer to "mature". When the better weather comes a bed takes about three to four weeks to dry out, and both locomotives are worked. It takes a gang of six men a whole day to empty a sludge bed, the dried sludge cake being removed in the skips to storage sheds where it is either removed by a contractor, or sold under the trade name of "Semeck" as a fertiliser. The Board now serves about 211,000 people in an area of about twenty-eight square miles. During the year 1962/1963 the railway handled 16,400 cubic yards of sludge cake, of which 250 tons were sold as "Semeck".

There seems to be no prospect of the closure of any of the three rail systems. That at Surbiton does not seem to have altered since its inception, while the Hunslet at Malden works has been given a complete overhaul. At the Hogsmill works, the tipping dock where sludge cake was formerly tipped into lorries seems to have fallen into disuse, but some of the track has recently been relaid in concrete. The main development, however, is the construction of some new drying beds on the far side of the river Hogsmill. These are 140 yards long by 50 yards wide, and are automatically scraped clear of sludge cake. The idea is to feed it into skips via a conveyor belt though, as yet, no rails have been laid up to these new beds. If they are, the future of the system will be assured.

(Since the above article was written, all the works mentioned have been taken over by the Greater London Council - Hon. Eds.)

"Mr. Dargan, the railway contractor, pays no less a sum than £30,000 a week in wages to his 50,000-odd employees." ("Hull Times", 10th September 1847.)