| THE INDUSTRIAL RAILWAY RECORD |

© AUGUST 1974 |

SIR ROBERT M

cALPINE & SONS LTDTHE END OF AN ERA

FRANK JUX

The civil engineering firm of Robert McAlpine commenced business in 1868, in Scotland. The first contract is said to have been for a signal cabin for one of the Scottish railway companies, and gradually business expanded along with the growth of railways and industry in Scotland. As the firm became established bigger contracts were handled, including many railway construction projects for the Caledonian, North British, Lanark & Dumbarton and other Scottish lines, as well as contracts at the Singer factory at Clydebank and the Dawsholm Gasworks in Glasgow. All operations were based on Glasgow, and it was not until after the First World War that the main workshops were moved to Ellesmere Port, later being based at Hayes. The main offices are now in London, but a Glasgow office is still retained.

In 1900 the firm came south of the Border to build the dry dock at Hebburn and went to Ireland in 1903 for construction work on the Waterford & Rosslare Railway, later completing the Strabane & Letterkenny Railway in 1906-1908. In the same period Scottish work included much work on railway projects, harbour works and at the Kinlochleven Aluminium Works. In 1908 the construction of Dunston power station at Gateshead was commenced: this was the first of many contracts for power stations, and a sign of changing times. Railway work dwindled, to be replaced by the construction of reservoirs, docks and power stations, nearly all of which were in England and Wales.

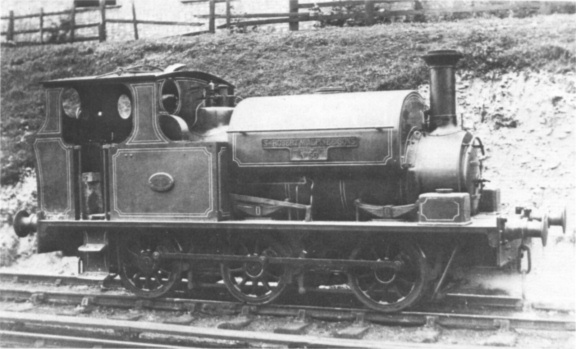

The most common of McAlpine's steam locomotives were the standard gauge inside cylinder 0‑6‑0 saddle tanks by Hudswell Clarke. McAlpine No.56 (Hudswell Clarke 1494 of 1923) at Sutton on 15th June 1929, during construction of the Wimbledon & Sutton line. (R.A. Wheeler)

Upon the outbreak of war in 1914, the firm became involved in the construction of munitions, aircraft, and other strategic factories, and did some work in France. After the war a number of large factories and chemical works were constructed, and several major road and housing projects undertaken. Contracts of particular interest to railway enthusiasts were those for the Welsh Highland Railway in 1923, and for the Crumpsall Vale Railway, Manchester, for British Dyestuffs Corporation (Blackley) Ltd in 1919-1921. Around the period 1921-1924 they were working on the Wembley Exhibition buildings, the Gosforth Light Railway and the Mersey Tunnel, while in 1924 work was commenced on a major overseas project for which locos were purchased[*], the Takoradi Harbour construction in Ghana (Gold Coast). From then until the Second World War a considerable number of road and dock projects was handled, and the Southern Railway Broadstairs - Ramsgate and Wimbledon - Sutton lines laid. Several sugar-beet factories were erected, and railway facilities built for London Transport. In 1936 a very large contract was commenced at the Ebbw Vale steelworks for which many locos were required; and by way of contrast work was performed at the new Elstree film studios.

At the beginning of the Second World War the government again required the firm's resources and power stations, ordnance factories, and other key plants were hurriedly built. Railway work included the Gloucester-Cheltenham rail link.

The aftermath of war included a chronic power shortage, and a large amount of work for new power stations was obtained as well as the operation of several opencast coal sites. Together with work for the railways, river boards and steelworks, these provided work for many of the remaining standard gauge locomotives, until their use was finally dispensed with.

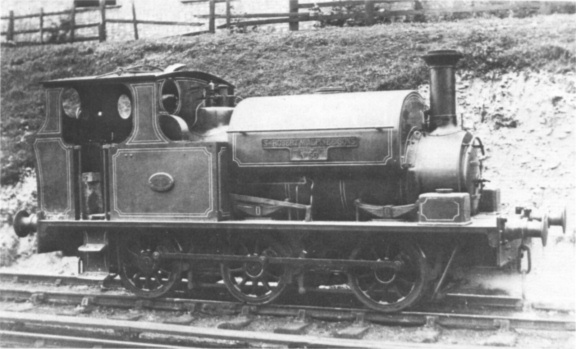

An unidentified McAlpine Hudswell Clarke 0‑4‑0 saddle tank at Cuffley on the GNR Cuffley - Hertford line contract of 1913‑16. 18th May 1913. (LCGB Ken Nunn Collection)

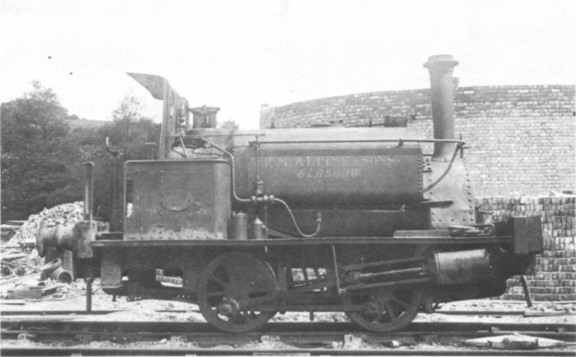

PALLION (Manning Wardle 1525 of 1902) at Neasden on 19th April 1913. Can any reader provide information on a McAlpine contract at Neasden which is reputed to have used this locomotive? (LCGB Ken Nunn Collection)

In 1868 construction equipment was rudimentary, and contracts were small. It was not until the 1880's that contracts became large enough to need the use of locos, and Barclay's supplied three or four of their standard 0‑4‑0 saddle tanks. These, with perhaps a few hired or second-hand locos sufficed until the late 1890's, when a batch of locos was bought from Hudswell Clarke, some of standard gauge, and some for the 3ft gauge. They were apparently successful, and the bulk of the steam locos acquired subsequently were from this builder. The railway projects naturally used standard gauge machines to haul materials, as well as spoil for embankments and cuttings, and the narrow gauge was used on jobs where standard gauge track could not usefully be employed. Everything went by rail, including concrete, dirt and materials. Most equipment was steam operated and manual labour more liberally used than today. The 3ft gauge seems to have been popular among civil engineering firms of the day, and steam locos of this gauge were bought until 1924. The surplus Simplex petrol locos available after the First World War no doubt caused the change to the 2ft gauge, and, apart from acquiring some of these, McAlpine's purchased new locos from Motor Rail both for the 3ft and later in quite considerable numbers for the 2ft gauge. The latter gauge was no doubt of lower capacity, but with the predominance of other means of hauling spoil narrow gauge lines have tended to be used for lighter work in any case. McAlpine's Simplexes have in the last decade been used for placing concrete and getting into the odd corners and tunnels.

Several locomotives were purchased for specific contracts and did not receive numbers in the McAlpine list. On the 2ft gauge there were some steam locos as well as dozens of petrol, diesel and battery locos, the battery locos including some built by Hudswell Clarke for the Mersey Tunnel contract. The 3ft 6in gauge locos 60‑67 were for the Takoradi contract, the Gold Coast Railways being of this gauge, and were unusual in that they were side tanks. 64 and 65 were returned to this country and, together with some of the 3ft gauge locos (presumably converted to 3ft 6in gauge) featured on several contracts, including the railway from Wimbledon to Sutton, before being scrapped. McAlpine's "standard" loco was an inside cylinder 0‑6‑0 saddle tank and for many years after World War 2 many were to be seen in the siding at Hayes, the numbers gradually dwindling as they were sold for scrap. Quite a number over the years were sold to customers when the job was finished, and some were still to be seen recently in power stations and sugar factories; one of these will be the last of McAlpine's former locos in service.

I would have liked to have been able to catalogue the work of the various locos. Contractors' equipment always has a hard time, as it works in site conditions, where it is difficult to provide adequate maintenance. On return to the depot at the end of each job it receives a major overhaul if it is thought that it will be required; otherwise it may be sold or scrapped. The nature of the construction industry gives uncertain employment to equipment; a large contract may require many locos (one at Tilbury Docks in the 1920's used twenty-seven locos), or only one or two (as did most power stations). The Ebbw Vale job called for locos far in excess of any the company could use continuously (over thirty-six were used there altogether) and consequently a number of surplus main line locos were bought for the job and sold afterwards. The War Department obtained several as they were desperately short of locos at this time.

The wanderings of No.9 (Hudswell Clarke 492 of 1898) may be of interest. It was purchased in 1898 for use in constructing the Fort William-Mallaig railway line. In 1903 it was on the Provan Gasworks job in Glasgow, then went to a reservoir contract at Motherwell. By 1909 it had emigrated south to another reservoir job at Molesey in Surrey. It was next heard of at the War Department MT Factory at Slough in 1919, and may then have gone to the London County Council Estate contract at Bellingham, where seven locos were employed. In 1925 it was on the Kent coast for the Broadstairs-Ramsgate railway, and in 1928 had gone to the Southampton Docks, where fifteen locos were used on the construction of a new quay. It was there for some time but in 1936 it joined with six others working on yet another reservoir job, this time at Northampton. When this was finished it went to Scunthorpe Steelworks (where there were eighteen locos) and is then said to have been sold to John Mowlem & Co Ltd.[†] Quite a record! However this was typical of the standard gauge locos. In many cases the lines on which they operated were self contained and their main purpose was hauling spoil. Otherwise they shunted traffic from the main line and moved internal traffic on the site. Operations must have been complex, especially where more than one gauge was used, and a line-up of locos would be a sight to remember.

Hudswell Clarke 1037, ex works on 25th June 1913, was delivered new to McAlpine at Merthyr Tydfil as a 3ft gauge locomotive, their No.34. It was photographed at Sutton on 5th August 1928 during construction of the Wimbledon & Sutton line of the Southern Railway, by which time it had been converted to 3ft 6in gauge and renumbered No.12. (R.A. Wheeler)

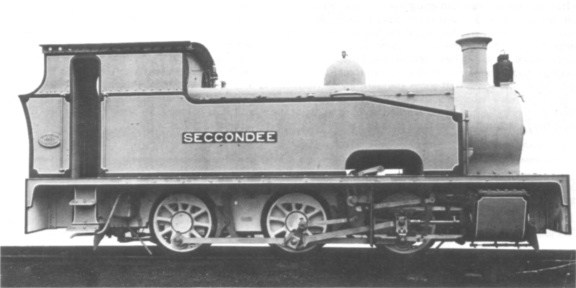

An official photograph of Hudswell Clarke 1551 of 1925, one of McAlpine's rather unusual 3ft 6in gauge side tanks, their No.60. It was the first of eight ordered by McAlpine for the construction of Takoradi Harbour in the Gold Coast. The name displayed was painted on the negative but was not carried by the locomotive: Seccondee was the Gold Coast port to which this batch of locomotives was despatched. It is thought that the box structure along the tank top is a very large tool box. (collection R.N. Redman)

The present-day firms of Sir Robert McAlpine & Sons Ltd and Sir Alfred McAlpine and Sons Ltd are both offshoots of the original firm. Their days of steam are over - but not forgotten.

(Member R.A. Wheeler is able to add a little to our knowledge of the Wimbledon-Sutton contract from personal experience. McAlpine had the contract for the Sutton to South Merton section of the Wimbledon & Sutton line, while the Southern Railway built the stretch from South Merton to Wimbledon themselves. Construction took place in the late 1920's. At the Sutton end of the line there were some heavy earthworks, and here McAlpine's used enormous steam driven excavators for the cuttings. The last stretch into Sutton - directly at the bottom of Mr Wheeler's garden at that time - was on a gradient of 1 in 44. He goes on to say:- "My cousin, who was then employed in the Civil Engineer's Dept of the Southern Railway at Waterloo, told me that whilst they realised that McAlpine's were good they always cut things pretty fine. What usually happened was that when the contract had only about six weeks to run before completion date, nothing had been done so the SR would write, pointing out the seriousness of the position. Back would come a reply, stating that everything was under control, and not to worry. Almost immediately after, masses of men and equipment would arrive on the scene and work would be carried on at top speed all day and all night, and seven days a week, the job usually being finished with about a couple of days to spare! This was what happened on the Sutton contract, the noise both by day and night being appalling, with the result that the local residents got an injunction against the firm compelling them to stop the night work. The engines used at the Sutton end were 3ft 6in gauge and I was told that they had been brought back from some breakwater contract in West Africa and hurriedly pressed into service for the Sutton job. McAlpine's also had some standard gauge Hudswell Clarke locos working on the line and they seem to have been very Hudswell Clarke minded as it was this builder's product or nothing in those days. Never have I seen industrial locos worked so hard as these were, and it says much for their robust construction that they were able to stand up to it all."

)* The only other overseas contract on which a loco is known to have been used was the construction of a breakwater at Kandia in Crete for which Henschel supplied a metre gauge 0‑6‑0 tank in 1925.

† No.9 was noted at McAlpine's Hayes depot in 1939 and probably went shortly afterwards to Mowlem who used it on the construction of the Swynnerton Royal Ordnance Factory in Staffordshire during the early years of World War 2: it disappeared from Mowlem's Welham Green depot, London, about 1944, presumably scrapped.

'Spot checks on engine drivers will be made by a special flying squad of Railway inspectors to ensure that engine drivers are not drunk and do not sleep on duty. Recently there were three rail accidents at Maho, Watawala and Potuhera. In one instance the driver was drunk. In another, the driver was sleeping on the job. The third accident took place due to a technical defect in one of the wagons. The railway authorities have taken departmental action against those responsible, pending an official enquiry. Meanwhile, engine drivers have also been warned that they face instant dismissal if they do not observe track signals.'

("Ceylon Daily News, "22nd October 1973.

– LAN)The 'Falkirk Gas Company's locomotive which is authorised to work over the Falkirk Gas Works Branch must give way to a railway locomotive proceeding in any direction on the Branch. To warn the Driver of Gas Works engine to get clear of the running line, Drivers of railway engines working to or past the Gas Works connection must sound the whistle at the entrance to Falkirk Iron Works when proceeding down the Branch, and at a point 200 yards from the level crossing when returning up the Branch.'

(LNER, Scottish Area, Sectional Appendix, dated 1st November 1947 – AN)

CASTLEHILL COLLIERY (SLAGHILL SIDINGS). 'MESSRS SHOTTS IRON COMPANY'S ENGINE will get possession of the line from the notice board, situated 100 yards north of the Slaghill loop to Carluke goods station, between 10.0 a.m. and 4.0 p.m. daily, and also, at any period of the day if this section of the line is not occupied by the L.N.E.R. Company's engine. In the event of a special trip having to be made from Castlehill Junction to Carluke goods station by the L.N.E.R. Company's engine between 10.0 a.m. and 4.0 p.m., the Shotts Iron Company's engine will stand aside to permit of the movement when requested to do so by the L.N.E.R. Company's Goods Guard.'

(LNER, Scottish Area, Sectional Appendix, dated 1st November 1947. – AN)

'The Kingston Locomotive Works, Kingston, Ont., has recently completed three contractors' locomotives for use in connection with the Soulanges Canal.'

(From "Industries & Iron," 16th June 1893. The 1896 edition of L.F. Vernon-Harcourt's "Rivers and Canals" states that the Soulanges Canal, 14 miles long, was then being constructed along the north bank of the St. Lawrence above the confluence of the Ottawa, to replace the Beauharnois Canal on the opposite bank. – KPP)

Golding Davis & Co's Works, Widnes. - 'On Friday morning at about eleven o'clock a man named Patrick Coyne met with a severe accident at the above works. He was engaged in filling "burnt ore" into a waggon on a siding and having occasion to move the wagon he went between it and another to push it. No sooner had he done so than an engine came up. The engine driver blew his whistle as usual but either the man did not hear or had not time to get out of the way before he was caught between the buffers of the two waggons. He was removed to the hospital.'

('Widnes Weekly News,' 29th June 1878. – JAP)