| THE INDUSTRIAL RAILWAY RECORD |

© JUNE 1975 |

NARROW GAUGE WAGONS

| LIME KILN WAGONS |

C.G. DOWN |

The two wagons which form the subjects of this article were both designed for use at lime kilns, and a few general points about such wagons can be made. In the South of England, where lime was obtained by burning chalk, kiln wagons as a distinct type did not apparently exist, and the quarry wagons were used to carry chalk to the kilns. Elsewhere, lime was obtained by burning limestone, but it seems most limestone quarries also produced crushed stone for civil engineering purposes and that only a portion of the output went to the kilns. The two wagons described appear to have been designed for the lime kiln side of the operations at two limestone quarries, and each was different from the wagons used for crushed stone.

The first example is a 1ft 11˝in gauge wagon at Henry Butt & Co Ltd, Milton Quarry, Weston-super-Mare, Somerset, which was measured in May 1968. This small quarry was opened in the early 1900's and used V‑skips (later road vehicles) in the quarry. The six lime kilns were served by a separate line which, together with the kilns, closed about 1966. At least four of these wagons, each slightly different, were cable hauled from a storage bin in the quarry, up to the kilns. All were built by Robert Hudson Ltd of Gildersome Foundry, Leeds; the wheels (11ľin diameter) and the "Faro" axleboxes are of standard Hudson design. The frame is somewhat unusual, being a pair of 10in by 3˝in steel channels riveted to the floor of the body. It seems likely that frames 10in deep were included to give sufficient height for clear tipping into the kilns, and the placing of the wheels well back towards the rear of the wagon is consistent with this. The body is a simple three-sided box of Ľin plate with Sin angle iron inside at the corners. Its inside dimensions are 53˝in long, 47ľin wide and 18in deep, giving a level capacity of about 24cu ft or 1 ton of limestone. Some of the wagons were fitted with a low door at the front, with a release catch worked from the rear. A point which slightly puzzles me is the socket bolted to the rear of the wagon; since none of the wagons had any couplings, I guess that the socket once held a forked rod to engage with an overhead haulage chain or rope.

The second wagon is a 3ft 0in gauge example from Flagstaff Quarry, Anglesey, which was measured in December 1973. Closed as long ago as 1941, this quarry used V‑skips and wooden tippers for its clean stone output, while the lime kilns were served by these steel wagons: three survived in a dilapidated condition, carrying numbers 61, 207 and 285, roughly painted in white on a black livery. It appears that stone for burning was once obtained from a gallery at the same level as the top of the kilns, but latterly it was brought from the lowest level of the quarry and hauled up an incline. Here too it seems that the wagons were designed to give a maximum floor height above rail level because the frames and three cross-members, all of 5ľin by 2Ľin channel, are surmounted by three 4in by 2in longitudinal channels. Apart from carrying the body hinge, there is no obvious reason for them other than to increase the height. Inside dimensions of the body are 5ft 0in wide, 6ft 4in long and 15˝in deep, giving an approximate capacity of 45cu ft or 39cwt. The wheels are 11˝in diameter on a wheelbase of 36Ľin, and the axles run in plain pedestal bearings. Once again, some of the wagons were fitted with a door.

|

|

|

|

1974 Aidan Fuller Memorial Trophy Photographic Competition

Entry.

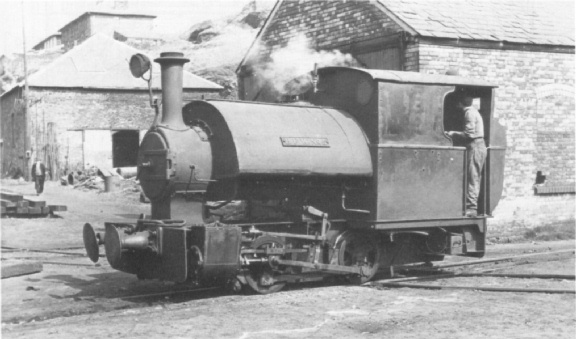

Guest Keen Baldwins Iron & Steel Co Ltd, Briton Ferry Steelworks, Glamorgan. BFW

No.5, a 2ft 4˝in gauge Bagnall (2062 of 1917) on 2nd April 1956.

(B. Mettam)