| THE INDUSTRIAL RAILWAY RECORD |

© FEBRUARY 1974 |

THE NORTH SEA CAMP RAILWAY

PHILIP J. ASHFORTH

In common with many other members of the Society, the narrow gauge railway system holds a special fascination for me, and if it is connected with one of the more unusual industries then all the better. So it was that I set out on a bleak December day in 1969 across the fenland adjacent to The Wash to study one such system: this is used in connection with a land reclamation scheme carried out by boys detained at the North Sea Camp, Frieston, a few miles east of Boston in Lincolnshire.

Reclaiming land from the sea in the area of The Wash is nothing new, for the Romans built an embankment to hold back the sea from The Haven to Skegness which was later improved by the Normans; this is still known as the Roman Bank. In more recent times unemployed youths from Jarrow were engaged on reclamation work along the coast during the early 1930's. The history of the railway at North Sea Camp really starts at the end of May 1935 when twenty boys arrived at the end of their long march from Stafford Prison to set up the second open borstal in the country. The rehabilitation scheme of reclamation work was begun in July 1936 with the building of an earth bank on the seaward side of the old Roman Bank. The bank had to be built to a height of 21ft 6in Newlyn[*] from a level of 10ft 0in Newlyn to ensure that even the highest tides would not flow over the top to destroy the work of many years labours. With the outbreak of the Second World War it was necessary for the embankment around the first enclosure to be finished quickly, and outside help was authorised.

Speed is not normally a very important consideration on this work, so manual labour rather than mechanical equipment is used: however, on 27th April 1949, a month after the third enclosure was started, the first two locomotives arrived. These were four wheel petrol machines fitted with a 500cc JAP engine unit, and built at the Dursley works of R.A. Lister & Co Ltd (their type RM2X). The rail system is 2ft 0in gauge and is divided into two sections - the farm lines running across the first two enclosures, and the temporary embankment lines which are lifted as work proceeds. A "main-line" joining the two systems runs roughly north-east along the foot of the Roman Bank before making a sharp turn to run east along the foot of the north embankment of the third enclosure until the new sea wall is reached. Reference to the track diagram will clarify this. Further mechanisation arrived in the form of a reconditioned 1953 Priestman Wolf Mark IIIB dragline which is used on the main embankment or on the seaward side of the bank to dig out the spoil required for the reclamation work. In September 1960 a third type RM2X loco arrived from Lister's, similar in dimensions to the previous machines but fitted with a Lister SL air‑cooled diesel power unit rated at 7bhp. This followed successful conversion of the other two locomotives in 1959 from petrol to diesel with 7bhp SL engine units supplied by Lister's.

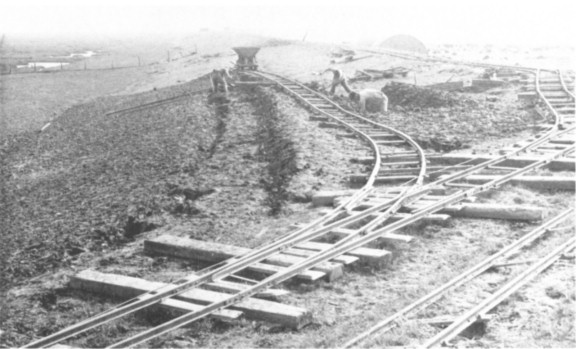

Reclamation work continued slowly until by 1956 the third enclosure had been closed from the sea and a start was made on filling the creeks. In 1959 work on the fourth enclosure began and this was completed in 1967. During a very high tide in 1969 the sea came dangerously close to the top of the embankment but fortunately did not go over. As a result of this it was decided to consolidate by strengthening and improving the bank rather than tackle any further reclamation work for the time being. This is being done at present by raising the height of the bank to 22ft 0in Newlyn to produce the profile indicated on the section diagram. The cross section of the bank is very important and to build it a temporary rail circuit is laid across the marsh on the seaward side to carry the spoil. The top of the embankment is built to the correct height whilst the bottom is also set by filling and packing to the exact slope required. Once the top and bottom have been set the rest is filled with spoil which is carried to the site in side tipping wagons in sets of three. During low tide the wagons are filled with earth taken from the marsh by the dragline, then pushed to the foot of the embankment in an anticlockwise direction and winched up the 1 in 4½ slope until the level is reached where the spoil is being tipped. The emptied wagons then continue in the same direction on the circuit to a point where the line drops back down to the marsh. The wagons descend the slope under gravity, their speed being checked by a boy with a wooden pole which is used as a brake, the wagons being released just at the right instant so that they run out across the marsh and draw to a standstill alongside the dragline. The track layout for the building of the embankment is also reproduced.

Reclamation work in progress. A general view of the embankment (upper) showing filling taking place on the seaward side, with (lower) a close‑up of spoil tipping. Note the desolate nature of the windswept landscape. (courtesy Lincolnshire Standard Group Ltd)

Lister 51917 standing on the 'main line' near the main camp complex in December 1969. (P.J. Ashforth)

Once the embankment has been completed there is the long job of filling in the creeks within the enclosure and here also the railway aids work. Sets of three side tipping wagons are filled with earth out on the marsh and are then pushed manually in an anticlockwise direction to the foot of the bank. The wagons are coupled to a trolley which in turn is connected by hawser to a diesel winch located at the top of the embankment: this pulls the loaded wagons up the incline, the line passing under the return part of the circuit on the way. Once on the level the locomotive takes over to act as a brake down the slope into the enclosure. The slope proper has a gradient of 1 in 1¾ but, where the railway runs across, the slope is built out in the form of a ramp with the gradient eased to 1 in 8. The loco is not coupled to the wagons so that at the right moment the throttle can be opened up to allow it to run on its own, straight over the points by the creek: the following wagons are switched to a short length of line leading to the part of the creek being filled. When the spoil has been tipped the locomotive is coupled to the wagons to haul them back to the top of the bank. By taking a run at the ramp it can just manage to pull three empty wagons to the top, where it is then uncoupled. Again the wagons are carefully controlled as they descend on the seaward side by means of a wooden pole used to chock the wheels until the point is reached where the wagons, when released, will roll to a standstill by the dragline. In both the building of the embankment and the filling of the creeks it is usual to employ two sets of three wagons, one set tipping whilst the other set is being filled with spoil.

At the moment there are four enclosures. The first (112 acres) is farmed, having had all its creeks filled in; the second (52½ acres) is partially farmed and also contains the sports field; the third (131 acres) is partly farmed but is mostly rough pasture for grazing; whilst the fourth (95 acres) is still being drained and having the creeks filled. This latter enclosure has yet to be ploughed for it takes about seven years for the rain to wash out the salt left in the soil.

Until 1970 an unusual load was taken by rail each morning - an insulated container with the cooked lunch for those out on the marsh! This was transported by flat wagon pushed by two boys. With the building of a roadway adjacent to the railway this job has been turned over to road transport. With reclamation moving further and further away communications between camp and site became sufficiently stretched to permit the purchase of a fourth locomotive: this was duly added to stock in December 1970, Lister's again being the supplier. Although this was a further type RM2X it differed from the previous ones in being fitted with a Lister SR1 power unit. Due to working in heavy mud and salt there is a high rate of repairs on the locos and the normal arrangement is for one locomotive to be on standby, one under repair, one working on the embankment whilst the fourth provides motive power for the "main line" between the camp buildings and the foreshore.

A fifth Lister arrived at the camp in July 1971, purchased second hand from Mr R.P. Morris for use by the farm department. On the farm lines trucks had previously been moved manually, all the locos being used by the works department on marsh reclamation. When purchased the locomotive was without an engine but it has since been fitted with a 22bhp Armstrong Siddeley diesel engine salvaged from a hay baler! Until 1971 all repairs to railway equipment were carried out in small huts on the work site, but a new engineering workshop was opened in 1972 on the fringe of the main camp area.

What of the future? It is proposed to continue reclamation northwards and it has been estimated that this could provide work for about 100 years, so there is a very good chance that this narrow gauge railway will survive for many years to come.

In conclusion I would like to thank the Home Office for permission to publish this article, also Messrs Guild (Warden), Selby (former Warden) and Wood (Engineer) - all at HM Detention Centre, North Sea Camp - for their help in its preparation.

Summary of locomotives (all 4‑wheel diesel mechanicals)

|

Maker |

Works number |

length (over buffers) |

Wheel diameter |

Weight |

| Lister | 33650 | 7ft 5in | 1ft 0in | 30 cwt (a) |

| Lister | 33651 | 7ft 5in | 1ft 0in | 30 cwt (a) |

| Lister | 31917 | 7ft 5in | 1ft 0in | 30 cwt (b) |

| Lister | 36371 | -- | 1ft 0in | 30 cwt (c) |

| Lister | 55413 | 7ft 6in | -- | -- (d) |

(a) New, ex works 26th April 1949; rebuilt from 4‑wheel petrol in 1959.

(b) New, ex works 9th September 1960.

(c) New, ex works 30th November 1970.

(d) ex R.P. Morris, Longfield, Kent, July 1971. Originally supplied new in 1967 to Bayliss Brickworks Ltd, Birmingham.

* The datum for heights on Ordnance Survey maps is 'mean sea level' at Newlyn, Cornwall, as measured between May 1915 and April 1921.

Hunslet featured their standard six‑coupled design in this advertisement which appeared in the issue of "Engineering" dated 7th April 1882. (copy courtesy R. Martin)