| THE INDUSTRIAL RAILWAY RECORD |

© FEBRUARY 1971 |

INDUSTRIAL RAILWAYS

OF BEDFORDSHIRE

| CORONATION WORKS, ELSTOW |

A. J. WARRINGION |

These works were opened by the Bedford Brick Company Ltd in 1935 (taken over by the London Brick Co Ltd in 1936) and a 2ft 6in gauge line was laid from the clay pits to the unloading sheds. However, as the working faces of the pits receded from the works, the petrol locomotives which had worked the line were dispensed with and the line was convened to cable haulage, in which form it exists today. The line leaves the unloading sheds and clay presses in a north-easterly direction and immediately turns through 180 degrees to continue in a south-westerly direction for nearly three-quarters of a mile; it then turns 90 degrees to the south-east and runs for about 600 yards, after which it again turns through 180 degrees and continues back the way it has come, along the edge of the pit and under the loading hoppers, back to the works.

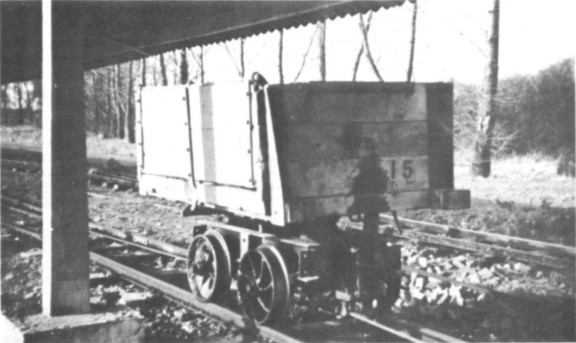

The wagons on this line are of wooden construction, and are of the "Ship Canal" type in design, but with a difference that they only tip on one side (to the right, facing the direction of travel), as the hoppers at the works are on one side of the line only. The wagons have average body dimensions 2ft 0in deep by 5ft 10in long by 4ft 0in wide. Wheels are 1ft 6in diameter, the older ones having seven curved spokes, but the newer ones are disc type with four holes. Some wagons have one or other of these types while others can be seen fitted with both! The wheels run free on the axles and are prevented from running off the ends by split pins.

In 1961 there were eighty wagons on the rope, with ten being kept as spares; they were painted black with white stencilled numbers. However, since then the Circuit has been extended as the pit faces recede and there may well be more on at the present time. The wagons run round the track in an anti-clockwise direction and the round trip in 1961 took about one hour. The wagons hold 1½ cubic yards of clay when filled level with the top.

In addition to the 2ft 6in gauge line, there were at one time two 2ft 0in gauge lines operating in the works. The first consisted of three isolated single lines running up steep inclines to the top of the kilns, where the wagons were run off to various points on top of the kilns by wagon turntables. By 1961 only two of these were in use, the third kiln utilising hand barrows. The wagons were the usual steel side-tipping type and carried slack coal for firing the kilns. They were rope-hauled to the top of the kilns whence they were propelled by hand. These lines were done away with sometime during 1963 and were replaced by hand barrows.

The second of the two 2ft 0in gauge lines was laid down inside the works between the presses and the kilns to facilitate stacking the bricks in the kilns before firing, and removing them afterwards. Bricks were stacked on flat "bogies" which were carried four at a time inside the kilns on traversers which ran the whole length of the kilns. This system was abandoned on 10th February 1961 in favour of motor trolleys.

Wagon 15 on the 2ft 6in gauge cable line in 1961. (author)

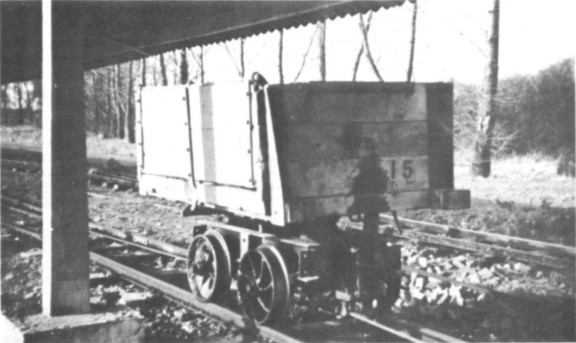

Apart from a period on loan to LBC’s Newton Longville Works in 1949, Aveling Porter 5935 of 1905 was at Elstow from 1940 until returning to LBC’s Calvert Works in 1950. (F. Jones)

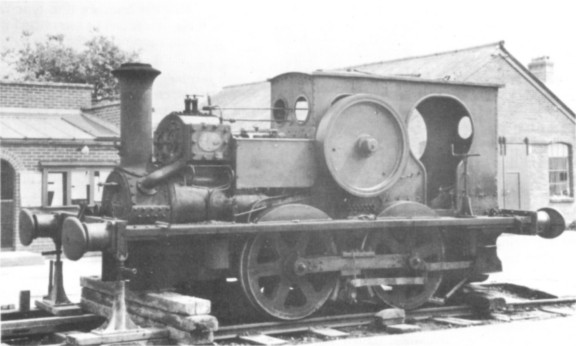

RUTH, the standard gauge electric locomotive,4th July 1964 (A. R. Etherington)

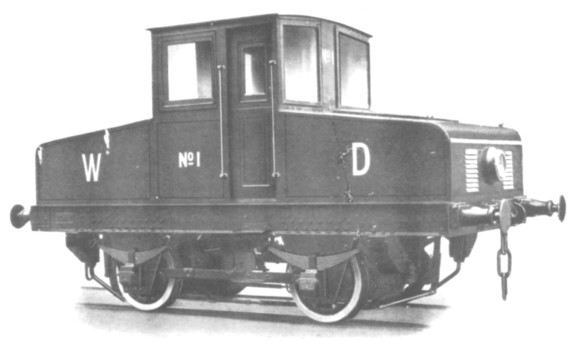

WD No.1 was a battery driven version of the overhead wire loco RUTH. This English Electric design underwent little or no change over a 20-year period. (English Electric Co. Ltd)

Apart from the narrow gauge lines there is also an electrified (overhead wire) standard gauge line which leaves the down side of the Midland main line at Houghton Conquest signalbox where there are several sorting sidings. It runs parallel with the main line in a north-easterly direction for about a quarter-of-a-mile, after which it veers off to the west and then splits into a number of separate sidings which serve the loading platforms at the kilns. The line is worked by a four-wheel electric locomotive named RUTH, which was at first painted light green but later became yellow and by 1961 was a dull red all over, including the nameplate. RUTH, English Electric 899 of 1935, is a 20ton "Type 3 Trolley Locomotive" with 3ft 2in diameter wheels and a wheelbase of 7ft 0in. Two English Electric type 32G 60hp traction motors (110 amps, 500 volts) produce a tractive effort of 5400lb (1 hour rating) at a speed of 8.3mph.

POSTSCRIPT. In December 1968 the continuous-circuit method of operation on the 2ft 6in gauge tramway was superseded by an end-to-end system. At the works a new line was laid from the north end of the building housing the presses to link up with the empty wagon route about 100 yards to the south; this link line rendered unnecessary the loop at the north end of the works. At the working face of the clay pit, the lines along the face (one carrying empty wagons and one loaded) were abandoned and replaced by conveyor belts which loaded the clay on to the tramway at a fixed point. A new connection was put in between the up and down lines at the conveyor loading point to change wagons from one line to the other. Presumably the reasons for these changes were firstly to reduce the wear on the tramway at curves and obviate the necessity for special pulley wheels to carry the rope round the corners, at which points very heavy wear occurred; and secondly, to save having to slue two lines of tramway as the working face advanced (one conveyor belt being much easier to move); and thirdly to prevent the tramway becoming of such a length that a very large quantity of wagons, rope and rail would be needed as well as making the round trip of each wagon extremely lengthy. In April 1969 the round trip took only thirty minutes, just half as long as it did in 1961.

BLACKWELL COLLIERY. "When the Blackwell Colliery Company’s engine runs over the Blackwell Branch between the loaded and empty sidings, it will be preceded on foot by one of the firm’s employees, who, on observing the approach of the Branch engine working between the New Hucknall Sidings and the Colliery will advise his Driver of the fact and take the requisite steps for disposing of the Colliery engine. The Branch engine must in all cases be preceded by the Guard on foot when running from the empty to the loaded sidings, and should the Guard observe the Colliery Company’s engine to be upon the Branch he must warn his Driver accordingly." (LNER. Southern Area, Sectional Appendix dated 1st November 1947. –

KPP)"Kilsyth Burgh Police Commissioners. – Supply of about 500 yards of cart tram rails or plates (single). Tenders to give full particulars, including weight, and whether single or double flange. Tenders [by Monday, 4th July 1892,] to Mr R. M. Lennox, Town Clerk, Kilsyth." (Iron, 1st July 1892. –

KPP)"BALDWIN LOCOMOTIVE WORKS. — Although some 13,000 men are employed and six locomotives are being built per day, it is found impossible to cope with the large orders that American railroads demand. Probably the largest order ever given for locomotives by one company is that now being executed for the Pennsylvania Railroad of 350 engines."

("The Locomotive Magazine", February 28th, 1903 –

KPP)