| THE INDUSTRIAL RAILWAY RECORD |

© DECEMBER 1963 |

WALTHAM CROSS GRAVEL PITS

by C. G. DOWN

In 1931, as part of its expansion programme, the Twickenham Gravel Co. Ltd. opened new gravel workings at Waltham Cross in Hertfordshire. The processing plant was situated by the Eleanor Cross Road, just east of Waltham Cross railway station, and the pit site was to be by a stream which flowed through fields about a quarter of a mile south of the plant. To connect the two areas a 2' 0" gauge railway was laid to bring the gravel up to the plant.

The first locomotives were of Motor Rail "Simplex" make, except for one by F.C. Hibberd (No.2620) which was constructed to a "Simplex" design and was therefore virtually identical to the others. All the locomotives were four-wheeled and had 20 h.p. Dorman petrol engines. Motor Rail 5041 was obtained from the newly opened Feltham Pits, while Motor Rail 5065 and the Hibberd were new. In about 1937 they were all rebuilt with National Gas diesel engines, and gained their red livery about this time too.

None of these original locomotives remained after 1953 when, due to their deteriorating condition, five more locomotives were obtained. The Hibberd went to Feltham Pits, where it still remains; two of the Motor Rails were scrapped, and the third went to the Brillma workshops at Hanworth. The five new arrivals were all of Hibberd make, again to "Simplex" design. Three (2389, 2631 and 2834) came from the War Department, the fourth (2384) from the Brillma workshops, and the fifth (2417) from an unknown source. One of the new engines (2834) went almost immediately to Feltham with 2620, and 2384 was scrapped although its frame was around until recently. These new locomotives were also painted red, and are numbered T 1 LO (2631), T 2 LO (2389) and T 3 LO (2417) in white on the cabsides.

The gravel pit has grown to be a large affair, and the railway track runs down the eastern side of it. There is a floating excavator here, and a small hopper mounted on caterpillar tracks which sits astride the lime. As the digging progresses along the pit, the line is extended or shortened, and the hopper is towed along by means of chains hooked to a locomotive or train.

The line runs north from here and soon turns northwest, crossing the stream on a small girder bridge. This is followed immediately by a long, though slight, adverse gradient, the track here being laid on a concrete base for about one hundred yards. Apart from this, the prefabricated track is laid directly on to the ground. After the concrete stretch the track gradually turns northwards again, crossing two mud tracks in the process. Now the line leaves the open fields and, running due north, dips into a narrow alley. The trees which line this hide to some extent the many contractors’ yards which back on to the line. Crossing a metalled road at the end of this alley, the line enters the works. Here are situated the fitting shops, a couple of disused sidings, and the cable hauled buckets where the skips are unloaded. The buckets bring the gravel to the screens, after which it is washed and crushed, and either loaded into lorries for shipment or stockpiled for further crushing. This stone is loaded into skips by a grab and passed through the plant again.

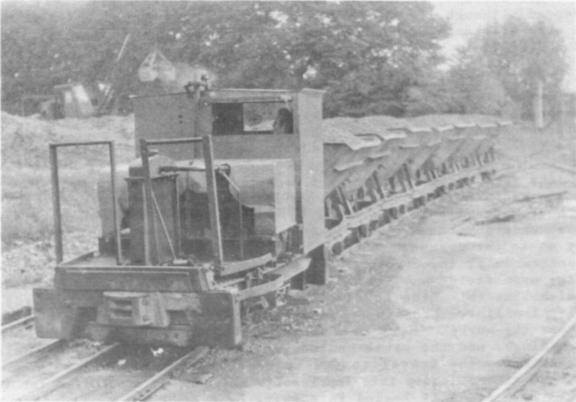

Trains consist of seven skips, and two trains are operated at a time. The full skips are drawn over the unloading point, and then pulled backwards round the loop as they are unloaded. Meanwhile another train has arrived on the other side of the loop and, when the first train has been emptied, the skips are propelled back to the pit while the second train unloads. By this means a continuous supply of gravel can be fed through the machinery.

T3LO with a loaded train on 30th August 1962. (C.G. Down)

There is an interesting piece of equipment in use on the line. At each of the three road crossings are traffic lights and bells to control road traffic. These are connected electrically to a lineside skate about two feet off the ground. A bar on the side of the locomotives will depress the skate and put the lights to danger for road users and also start the bells ringing. Extra warning is provided by whistles on the locomotives. These are hinged over the exhaust pipes so that, when a cord is pulled, the whistle rises over the pipe to give a somewhat intermittent note.

The locomotive story is not yet complete. After July 1962 the track was being gradually relaid to accommodate a heavier locomotive. This arrived during March 1963, and was put into operation on the 14th of that month. A four wheeled diesel locomotive (Ruston & Hornsby 398099), it arrived in green livery fresh from overhaul at the Chertsey workshops of the Ham River Grit Co. Ltd. ‘having previously worked at their Eastbrook Farm Pits at Dagenham. This additional locomotive enables one of the others to be under repair with no detriment to operation of the trains. The spare cam also be used for hauling the primary processed gravel for recrushing, a job previously performed by one of the train engines in between duties.

Despite this new lease of life, the line will probably be virtually discontinued in 1964 and replaced by dumper trucks.