| THE INDUSTRIAL RAILWAY RECORD |

© APRIL 1975 |

2. LOCOMOTIVES

Trevithick's locomotive

It is widely known that Richard Trevithick built the first railway locomotive; and many people still imagine that it was the Penydarren engine of 1804. In fact he made one in 1802‑3 for the Coalbrookdale Company in Shropshire, the first firm to take an interest in his high pressure engine after the patent of 1802, though it is far from certain whether this engine actually ran. He next interested Samuel Homfray of Penydarren Ironworks in his engines; he built several stationary ones here, and on 1st October 1803 he wrote to his patron Davies Giddy, "There will be a realroad engine at work here in a fortnight; it will go on reals not exceeding an elevation of one-fiftieth part of a perpendicular [presumably meaning 1 in 50] and of considerable length. The cylinder is 8½ in diameter, to go about two and a half miles an hour; it is to have the same velocity of the piston rod. It will weigh, water and all complete, within 5 tons". Trevithick was over-optimistic about completing the engine, for he was diverted to other work and it was not put together until four months later. The background to its building was a bet of 500 guineas made by Homfray with Richard Crawshay of Cyfarthfa that he would haul a load of ten tons of iron from Penydarren to Abercynon and the empties back; the stakes were held by Richard Hill of Plymouth works.

Trevithick wrote to Giddy on 15th February 1804: "Last Saturday [11th February] we lighted the fire in the Tram Waggon and work'd it without the wheels to try the engine; on Monday we put it on the Tram Road. It work'd very well, and ran up hill and down with great ease, and very managable. We had plenty of steam and power". This trip, on 13th February 1804, was the first recorded run by a railway locomotive. On the 20th Trevithick wrote again: "The Tram Waggon have been at work several times. It works exceeding well, and is much more managable than horses. We have not try'd to draw but ten tons at a time yet, but I dought not but we cou'd draw 40 tons at a time very well for 10 tons stands no chance at all with it. We have not been but two miles on the road and back again, and shall not go further untill Mr Homfray comes home. He is to dine home to‑day, and the engine will go down to meet him. The engineer from Government [Simon Goodrich] is with him. The engine, with water encluded, is ab't 5 tons. It runs up the Tram road of 2 Inch in a Yard [1 in 18, perhaps on the Dowlais section] 40 stroakes per min't with the empty waggons. The engine moves forth 9 feet every stroake. [i.e. just over 4mph] The publick is much taken up with it. The bet of 5 Hund'd Guineas will be desided abt the end of this Week ... The steam thats disscharged from the engine is turned up the chimney abt 3 feet above the fire, and when the engine is working 40 St pr mt, 4½ ft Stroake, Cylinder 8¼ In Diam, not the smallest particle of steam appears out of the top of the chimny, tho' the Chimny is but 8 feet above where the steam is delivered into it, neither is any steam at a distance nor the smallest particle of water to be found. I think its made a fix'd air from the heat of the Chimny. The fire burns much better when the steam goes up the Chimney that what it do when the engine is Idle. I intend to make a smaller engine for the road, as this has much more power than is wanted here. This engine is to work a hammer..." Trevithick intended to meet Homfray, set his coach on the tramroad (which apparently it would fit) and haul it by engine; unfortunately we do not know if this journey took place.

The trip to decide the bet in fact was made on 21st February. Trevithick wrote next day: "Yesterday we proceeded on our journey with the engine; we carry'd ten tons of Iron, five waggons, and 70 Men riding on them the whole of the journey. Its above 9 miles which we perform'd in 4 hours & 5 mints, but we had to cut down som trees and remove some Large rocks out of the road. The engine, while working, went nearly 5 miles pr hour, there was no water put into the boiler from the time we started untill we arriv'd at our journey's end. The coal consumed was 2 Hund'd. On our return home abt 4 miles from the shipping place of the iron, one of the small bolts that fastened the axel to the boiler broak, and let all the water out of the boiler, which prevented the engine returning untill this evening". The Cambrian of 24th February confirms the essentials of this account, and adds that "it is not doubted but that the number of horses in the kingdom will be very considerably reduced, and the machine, in the hands of the present proprietors, will be made use of in a thousand instances never yet thought of for an engine". Homfray was delighted; the engine, he said, "goes very easy 4 miles per hour and is as trackable as a horse, will back its load and move it forward as little (and slow) at a time as you please. With this engine we can make a difficult tryal and I am now preparing a pump to lift water, a barrell to wind a ball up and down".

Hill, as stake-holder, proved to be a hair-splitter. "Mr Hill", lamented Trevithick, "says he will not pay the bet, because there were some of the tram-plates in the tunnel removed, so as to get the road into the middle of the arch. The first objection he started was that one man should go with the engine without any assistance, which I performed myself without help; and now his objection is that the road is not in the same place as when the bet was made". His next niggle was that the engine did not return the empty trams in the same time as horses usually did because the forcer pump could not fill the boiler which had to be refilled with cold water. We do not know if the bet was ever honoured.

The engine was used several times more. On 4th March Trevithick said that he had tried it with 25 tons of iron, for which it was more than a match. He was then preparing, in accordance with Homfray's scheme, to show a party of London engineers (who never came) a series of experiments whereby the engine would pump water, then work a hammer, then wind coal, and finally haul iron on the tramroad. "The steam", he says in this letter, "is delevered in to the Chimney above the damper, and when the damper is shut the steam then makes its appearance at the top of the chimney, but when open none can be seen. It makes the draft much stronger by going up the Chimney; there is no flame that appairs". In April the engine was being used for pumping water; a letter by Homfray says that the boiler was cast iron, 6ft long and 4ft 3in diameter, that the cylinder was 8in diameter, raising water a height of 28ft by a pump 18¼in diameter and 4ft 6in stroke at 18 strokes a minute. But before early July it hauled at least two trains. Thereafter it seems to have run no more on rails. There are various versions of its latter days: driving a hammer at Penydarren, winding at Penydarren coal pits, working the incline at Cwmbargoed, winding at Cyfarthfa, or a combination of these functions. It may have survived in this guise into the 1850s.

This is the sum of the useful contemporary evidence. From it we can be sure of several things. There was a single cylinder 8¼ in by 54in; the primary sources do not say whether it was horizontal or vertical, and in other engines Trevithick used both types, recessed completely into the boiler. But a vertical cylinder is ruled out in this case, since the end of the piston rod at the top of the stroke would be a good 9ft above the base of the cylinder, and Plymouth tunnel was only 8ft high. The boiler was cast iron 4ft 3in by 6ft. The chimney stood about 11ft high above the firebox, and must have been lowerable to pass the tunnel; the moving of the track in the tunnel , was most likely to allow the flywheel to fit. Though there is no direct evidence for the flywheel, it is difficult to imagine that there was not one. The exhaust was turned into the chimney where Trevithick found that it helped the fire to draw. The later "Battle of the Blast Pipe" was thus largely a vain one, since the principle dated back to the beginnings of the locomotive and the only real improvement of later days was Hackworth's nozzling of the orifice. The engine weighed about 5 tons in working order, and travelled at 4 to 5mph. The statement that "the engine moves forth 9 feet every stroake" is not crystal clear, but it surely ties in with Trevithick's earlier remark that "it is to have the same velocity of the piston rod", namely that for each single 4ft 6in stroke of the piston it travelled 4ft 6in on the rails, or 9ft for each return stroke. If this is so, and the gear ratio was 1 to 1, the wheels were rather over 2ft 10in in diameter; but this is only guesswork. Geared it must have been, though, in view of the enormous stroke. The engine could be put to non-railway work without its wheels, which implies a belt drive off the crankshaft or a crank drive off the flywheel.

There is a fair amount of secondary evidence for Trevithick's engine — early technical books purporting to describe it, and the memories of local engineers and ordinary folk recorded mainly in the 1850s. This information, not being contemporary or provided by the protagonists, is not entirely to be trusted. Some is blatantly untrue: that the engine had two cylinders, that the cylinder was vertical (and of different dimensions to those Trevithick gave), that the wheels were driven directly by connecting rod, that the engine had a brick chimney (a persistent local legend, this), that the boiler was wrought iron, that the engine only made one trip. Some stories may conceivably be true (for example that the engine was banished from the tramroad because it broke both axles); some probably are true (that it had a feed water heater, that William Richards was the driver); and all which mention these matters are agreed that the locomotive had four wheels, a blast pipe, and a return flue boiler. The recollections of Rees Jones, written down in 1858, are more trustworthy than many, allowing for the fading memory of an 82‑year-old. He was overlooker of the Penydarren engines in 1804, and said that most or all of the work for the locomotive was done at Penydarren. Richard Brown made the boiler and smithwork, and Jones himself did most of the fitting. The engine was first used to bring iron down from the furnaces to the forge, where it worked well but broke many plates and couplings. It then hauled iron down to Abercynon, again breaking many plates. Jones got some details wrong, but confirmed others, and added that the pressure was about 40 Ib/sq in and that steam distribution was by a typical Trevithick four-way rotary cock.

There remains the famous drawing made by John Llewellyn who worked with Trevithick at Merthyr. It is a pricked copy of an earlier drawing, a little crudely done, and it came to the Patent Museum (now the Science Museum) in 1855 via Llewellyn's nephew and William Menelaus, manager of Dowlais. It shows a plateway locomotive with cast iron return flue boiler (the box at the boiler back is probably to connect two separate flue tubes, in place of a single bent tube), with a horizontal cylinder enclosed in the boiler above the fire, return connecting rods from the crosshead to a crankshaft with a large flywheel, and a drive to the wheels on one side only via pinions on crankshaft and axles and one intermediate gear. It has a rotary steam valve and wheels loose on the axles. The legend on the drawing reads: "Tram Engine. 4¾ inches diar of Cylinder. 3 feet Stroke. Decr 1803". There is no other scale. This drawing is still frequently taken to represent the engine that first ran on 13th February 1804, and as such has been copied, miscopied, described, misdescribed and imaginatively interpreted on countless occasions. But as has been pointed out several times in the past, this simply cannot be the case. The cylinder dimensions given in the legend are much too small. Also, by using the throw of the crank (1ft 6in) as a measure, the gauge of the wheels scales at just over 3ft, not the 4ft 6in or thereabouts necessary for running on the 4ft 4in outside gauge of the Penydarren Tramroad. It has been suggested that it is a copy (size for size, because it is pricked off) of a drawing of the original engine, but with the scale altered to give a general idea of the smaller locomotive that Trevithick said he intended to build in his letter of 20th February. Another suggestion is that the legend is a false one, added considerably later when the true scale of the drawing had been forgotten. In both cases, the theory is that the legend or scale on the original gave the stroke as 4ft 6in. These two ideas can be dealt with together. Firstly, the legend has every appearance of being early nineteenth century in style. Secondly, if the stroke were 4ft 6in, the gauge would be 4ft 6in, which fits perfectly, and the boiler would be about the right size; but not one of the other dimensions agrees with contemporary statements. The chimney, for instance, is much too short; the flywheel is far too high; and the distance travelled per return stroke would be 14ft (or 7ft per single stroke) instead of Trevithick's figure of 9ft. Lastly, if the stroke is 4ft 6in, the scale of the drawing is 2/3 in to the foot, a curious one; if the stroke were 3ft as the legend says, the scale is the eminently reasonable one of 1in to the foot. To my mind, there is no question: this is not the Penydarren engine. It really is a 3ft gauge engine.

What then is it? It is certainly a Trevithick design — there are no other candidates — and equally certainly the famous Penydarren engine must have had a family resemblance to it, though the details clearly differed. Two possible claimants present themselves. One is a hypothetical engine for the internal Penydarren system (which was of 3ft gauge). But the smaller engine which Trevithick planned in his letter of 20th February was apparently intended for the main tramroad (4ft 6in gauge), and there is no other suggestion that a narrower gauge engine was ever contemplated, let alone built. The second and more probable claimant is the Coalbrookdale engine. Here we have a little more to go on. One of the plateway gauges in that district was 3ft (notably the main line from the Dale to the Severn wharf); Trevithick refers to one of his engines there, possibly the locomotive, as having a cylinder 5in by 3ft; and the locomotive cylinder is said to have survived until 1884 when a casual visitor describes it as of 4in diameter and about 3ft stroke, figures which agree roughly with those on the drawing. On this interpretation, the drawing may have been made to show Homfray the kind of engine he was going to get.

It is not likely that Homfray envisaged Trevithick's locomotive as a permanent replacement for horses in hauling Penydarren iron. Both he and Trevithick apparently regarded it as an experimental multi-purpose machine which would demonstrate the compactness, power and versatility of the new high pressure engine. In any event, it proved the point which became increasingly obvious later, that cast iron rails and locomotives did not go well together; wrought iron rail was an essential prerequisite for the full development of the railway engine. Plates broke aplenty under the loaded trams with a maximum gross weight of 3 tons; many more broke under the 5 tons of the engine. Davies Giddy wrote at the time that because of these breakages "on the whole the Experiment was considered as a failure". But at least it had shown the way, and proved that steam power would haul useful loads on rails by simple adhesion.

ECLIPSE

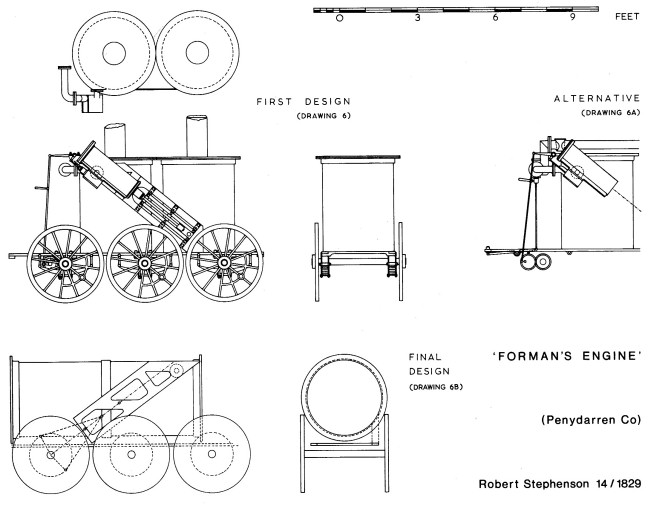

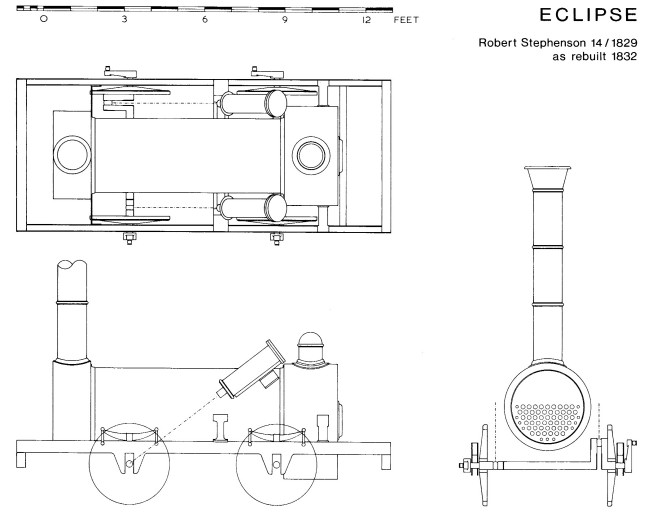

After 1804, apart from the odd isolated experiment [1], South Wales knew no locos until 1829, when the first of a long series of industrial engines arrived. Robert Stephenson & Company were the first in the field with a locomotive ordered in November 1828 by William Forman, by then the senior partner in the Penydarren works. The original plans, undated but attributable to late 1828 or early 1829, show an 0‑6‑0 with twin vertical boilers after the fashion of the TWIN SISTERS then being built as the first engine for the Liverpool & Manchester. It was to have plateway wheels 3ft in diameter and set at 3ft 1½in inside gauge for running on rails of 3ft gauge, steeply inclined cylinders and valve motion driven by gears on the rear axle and by rocker arms. But the design was drastically changed, for an outline drawing dated July 1829 shows a horizontal boiler 2ft 9in by 7ft 2¾in, and the Engine Description Book confirms that as built the engine had a single non-return elliptical flue (this being just before the ROCKET and the multitubular boiler). The chimney was no doubt bent up through 90 degrees from the front of the flue. The cylinders, 7in by 20in, were inclined and mounted on the boiler back; the frames were of flat bar 3in by 1in, and the wheels were 3ft. The works number was 14 (not 16 as Dendy Marshall and others imply). The Penydarren engine, in a packing case, was dispatched by sea from Newcastle on 18th July 1829, together with BRITANNIA for Tredegar which, though smaller, it much resembled; and it was delivered at the Tredegar Iron Company's Pillgwenlly wharf at Newport whence it was presumably taken on to Penydarren by road. It cost £375 plus £19 odd for freight, packing and extras.

The engine, apparently nameless, hauled trams on the internal Penydarren system for two years or so before being returned to Stephensons in 1832 for conversion to 4ft 6in gauge — the Penydarren Tramroad gauge plus 2in play. The boiler shell was retained but given 82 copper tubes, a smokebox and a vaulted firebox with dome on top; the heating surface now totalled 289.75 sq ft (so the Description Book, but the drawings show only 60 tubes). The cylinders remained in the same place, but new axles were needed with the cranks inside the wheels, and a new sandwich frame, typical of Stephenson practice of the period, was fitted outside the wheels. The arrangement was altered to 0‑4‑0, with new wheels of 3ft 6in diameter (according to the Particulars Book; 3ft 2¾in or 3ft according to the drawings; 3ft 4in according to The Cambrian). The chimney stood 12ft 7in high above rail level, and though the drawing shows it fixed, it must have been lowerable to pass through Plymouth tunnel. The engine that resulted from this metamorphosis was in general very like the standard four-coupled Stephenson 'Planet' type of the time, except for the inclined cylinders which were old-fashioned by then.

In this new guise the engine began to work on the Penydarran Tramroad on 22nd June 1832. The Cambrian described the occasion:

On Friday last a new Locomotive Engine, called the Eclipse, started from the Penydarran Iron Works, Merthyr Tydfil, with a load of 23 tons of bar and rod iron, which was delivered at the basin of the Glamorganshire Canal, 10 miles from the works, in one hour and forty-eight minutes. — The engine then returned with the empty carriages, crowded with passengers, whom the novelty of the occasion had attracted, and reached the works, in one hour and 45 minutes, from the time of its leaving the basin, including all stoppages on the road for water, &c. — This was performed twice in the course of the day, and had-there been occasion, it could have made another trip with the greatest ease. The day following it came up from the same point, drawing the same number of carriages, and conveying 145 passengers, in one hour and 14 minutes, including stoppages; and as preparations are making to obviate the necessity of taking in water on the road, it is expected that the journey will be accomplished in future easily and safely in an hour. This engine was built at Newcastle-upon-Tyne, by Messrs Robert Stephenson ... it has been much admired for the symmetry of its proportions, and being very low and compact in general appearance, conveys to the mind a pleasing idea of smugness and aptitude for the task assigned to it. The means of generating steam is so abundant that it was blowing off at the safety valve nearly the whole length of the journey forward and back, and the appearance of the engine altogether puts one strongly in mind of one of those low built craft, which although buried in the spray, and scarcely appearing above the water, yet sweep through it with the ease and swiftness of a Dolphin. It has two 7‑inch steam cylinders of 20 inches stroke, is mounted on four wheels 3 feet 4 inches in diameter, and weighs, when the boiler is charged with water, and in working trim, about five tons.

How long the ECLIPSE continued to work is unknown, though we can hazard a guess at its final home. The accepted (but inaccurate) list of early Stephenson products gives number 14 to DUDLEY, supplied in 1828 to the Earl of Dudley. This cannot be, since the original Stephenson papers are quite ignorant of it, and the historians of the Pensett Railway make it clear that apart from AGENORIA there was no locomotive on the Dudley system so early. But they do say that the line acquired a second-hand engine, details unknown, in 1846; and though the cylinder dimensions ascribed by the list to DUDLEY (9in by 24in) differ from ECLIPSE'S (7in by 20in) the works number coincides. Penydarren may therefore have sold ECLIPSE directly or indirectly to Staffordshire, where it would need new wheels for the standard gauge. DUDLEY is said to have been rebuilt as an 0‑4‑0 saddle tank at Castle Mill in 1906.

No other Penydarren Company locomotives are on record, and the rest of the story concerns the Dowlais Iron Company alone.

1: A Blenkinsop rack engine was probably supplied to Nantyglo about 1813; just possibly a locomotive by William Stewart was tried on the Monmouthshire Canal Company's tramroads in 1816; and an engine of unknown origin was running on a tramroad somewhere between Briton Ferry and Swansea in 1819.

PERSEVERANCE

The locomotive was far from being a commonplace by 1829, and the plateway locomotive was even less so. Up to 1829, only about a dozen of them are known to have existed, of which Trevithick's was the only certain example in Wales, though the engines already mentioned at Nantyglo and near Swansea are other possibilities. From 1829 onwards, however, while the edge-rail engine leapt forward, the plateway engine also enjoyed a limited flowering. After that date, about sixty are known, of which some fifty were in South Wales, most of them on the intricate system of tramroads owned by or feeding the Monmouthshire Canal. As a type, the plateway locomotive has been distressingly neglected, but in many instances the builders showed marvellous ingenuity in producing designs suited to the peculiarities of the area. They deserve far more attention than they have received; and a major source is available in the large collection of drawings of the Neath Abbey Ironworks, a Quaker firm founded in 1792, which between 1830 and 1874 produced a total of at least 50 locomotives of all types, both edge and plate. All six engines in the Dowlais plateway stock came from their stable. Our knowledge of them is increased by the voluminous (but incomplete) letters received by the Dowlais Iron Company.

The Dowlais correspondence regarding the order and development of the first engine has unfortunately not survived, and until the maiden trip we have to rely on the drawings alone. The first item is a drawing dated 31st August 1831 which is no longer in the collection but was reproduced by Dendy Marshall. It seems that the Dowlais engineers gave Neath Abbey a rough specification for the engine they wanted; Charles Jordan, the Neath Abbey designer, then translated this into a general drawing which was sent to Dowlais for criticism. In this instance the design was evidently not accepted. The drawing in question depicts an 0‑4‑4‑0 articulated geared rack engine — the rack for the 1 in 16½ section of the Dowlais tramroad. The inclined cylinders at the front (20in stroke and probably 10½in diameter) drove a central crankshaft, from which gears drove the inner axles of both pivoting bogies, whose wheels were coupled. The drawing shows these gears with straight faces whereas they should have been curved. Also on the crankshaft was a small pinion which could be slid either to engage a clutch on the main adhesion gearwheel or to mesh with the rack drive gear. The design — like its successors — thus allowed for either adhesion or rack drive: not both together, because of the differing size of the running wheels and the rack wheel. It is not clear whether the rack wheel remained down or could be raised clear. The rack rail was to be immediately on the inside of one running rail. The springs were set between boiler and main frame, not between wheels and bogie frames. Whether the boiler was intended to be multitubular is not clear; it certainly had a flue-type firebox of typical Neath Abbey pattern and a domed front. There were to be two chimneys, one on each side, standing 15ft 7in above rail level; because of the tunnel they were to be lowerable by means of a handle, chain, pinion and toothed semicircular bracket. A single chimney lowered on top of the boiler would still have been out of gauge. No details are given of steam pipes or valve gear. The unflanged wheels were 1¼in wide on the tread and 3ft in diameter.

Though the engine was not built in this form, the design was advanced for its day. Rack engines were hitherto restricted to the Blenkinsop and Murray type used on the Middleton and Kenton & Coxlodge waggonways; at Orrell Colliery; probably at Nantyglo Ironworks; and at two German sites where they failed miserably. Colonel John Stevens had also built an experimental rack engine in America. All these were rack only, with no ordinary adhesion drive. It was Neath Abbey which introduced the idea of using rack as an auxiliary drive for steep gradients. The concept of the bogie, invented and patented by William Chapman, had hitherto been adopted on only one of his locomotives (Heaton waggonway, 1813) — the famous Wylam engines, though eight-wheeled, did not apparently have pivoting bogies. This was also the first time an articulated locomotive was envisaged; the first to be built was Horatio Allen's SOUTH CAROLINA of 1832. Though rejected by Dowlais, the design was re‑used by Neath Abbey for a locomotive built for the Rhymney Iron Company in 1838, where the basic arrangement was very similar but the cylinders were at the rear and the chimney was single and non-lowerable.

Dowlais was quick in rejecting the plan, for on 14th September 1831 Neath Abbey produced another drawing for a rather simpler engine. It approaches the final design as actually built in the form of PERSEVERANCE, to be described shortly; but it had a shorter boiler, a shorter wheelbase and a flat front to the boiler with a small and awkward smokebox near the base from which a vertical flue rose to a pair of swivelling chimneys. The cylinders project much more behind the boiler, and on the crankshaft a clutch puts either the adhesion drive pinion or the rack drive pinion into mesh. The cylinders are 10½in by 20in, and the wheels 3ft 1in in diameter. Evidently the design met with approval from the Dowlais engineer, who endorsed the drawing for the guidance of Neath Abbey: "The Engine including boiler wheels &c complete not to exceed 8 Tons. The difference in level of the Boiler in some parts of the Road will be 2 Ins p Yard. The Horizontal Tubes would be preferred in the Boiler if Mess. Neath Abbey Co who are responsible for the performance of the Engine think proper. Speed of Engine 7 Miles p hour. The Engine to be reed to put on the Road before the 25th March".

Having established the general idea, Neath Abbey proceeded to amend the design in most of its details, and there are no more general arrangement drawings. Instead there is a series of fifty drawings of components dated (where they bear a date at all) between 14th October 1831 and 23rd May 1832. From these the overall drawings given here have been built up. But there are many difficulties in using the Neath Abbey drawings. Details were clearly evolved as work proceeded; for some parts there are conflicting versions, and the exact location of other components — such as the dome, steam manifold and feed pump — is a matter of deduction and may be slightly wrong. For some parts, especially safety valve and control levers for rack, clutch and reversing, there are no drawings.

The original name given to this engine was SUCCESS, but in May 1832, before it was finished, the name was changed. On several drawings "SUCCESS" has been crossed out and such words added as "now called PERSEVERANCE". Unfortunately in the very same month several drawings of INDUSTRY, then being built for Harford Davies & Company of Ebbw Vale, were altered in just the same way. Both engines were 0‑6‑0's, with 10½in cylinders, lowering chimneys, and the same gauge; and it is quite possible that only one of them should have had its name changed. Which? The motto of the Sirhowy Tramroad, in which the Harfords had a large stake, was "Perseverance" — and this would therefore be a reasonable name for their engine. "Perseverance", however, was also the motto of the Glamorganshire Canal Company, which the Penydarren Tramroad joined but with which it was in rivalry. Whatever the truth, the name PERSEVERANCE stuck to the Dowlais engine; whether it did to the Ebbw Vale one is not certain.

The Dowlais PERSEVERANCE was a geared 0‑6‑0, with cast iron wheels 3ft 1in in diameter of a pattern favoured by Neath Abbey. The frame, like that of its successors, was singularly slight, made of flat bar iron 3in by 1in with stayed cross members near the ends for the coupling bars. Francis Trevithick tells us that in 1837 he rebuilt a Neath Abbey engine on the Penydarren Tramroad, for which PERSEVERANCE is the most likely candidate: 'The double or breeches fire-tube in the boiler", he says, "was removed to make room for thirty small tubes, such as were coming into use for locomotive boilers". As early as 1834 Neath Abbey had supplied spare "tubes" for PERSEVERANCE, but these could as easily be large tubes for a simple double flue as small ones for a multitubular boiler. The boiler plates were ⅜in thick. There was a domed front to the boiler, acting perhaps as a crude smokebox, on which was mounted a box which held the swivels of the two chimneys. These reached a height of about 16ft above the rails, were held up by diagonal stays, and (according to the invoice) were raised by winch, though the drawings give no details. The 10½in by 20in cylinders were inclined and set at the back of the boiler, a position inaugurated by Robert Stephenson in 1828, but at variance with Neath Abbey's early preference for vertical cylinders and a bell-crank drive, or horizontal cylinders and a rocking beam drive.

The crankshaft was mounted on bearing frames attached at either end to the horn blocks of the front two axles, so that it was sprung. It carried the driving pinion A, which could be slid sideways along a square section of the shaft by a sheave operated by crank and rod from the footplate. For adhesion drive, pinion A engaged gear B (which was loose on the crankshaft) by means of a clutch, and B drove the front two axles by gears C and D, while the rear axle was driven by coupling rods. For rack drive, B was left idling and A was slid back to mesh with gear E on a short axle which carried the rack wheel F. When not in use, the rack axle was raised to clear pointwork. Its bearings were mounted on a U‑frame, whose opposite end was raised or lowered by lever from the footplate. The U‑frame was carried centrally on two large hoops, one attached to a crankshaft bearing frame, the other to a similar cross frame between the main axles; the latter hoop was wide enough to allow the pinion A to slide through it. Like the earlier design, PERSEVERANCE could not run by adhesion and rack at the same time; by adhesion it travelled 9ft 8in per revolution of the crank, by rack 3ft 11in. The cast iron rack rail, with teeth at 6in pitch, was laid with its centre line 1ft 2in from the outer face of the running rail.

The details of the valve motion are not precisely given, but they seem to have followed contemporary Neath Abbey practice in those days before link motion or even gabs. Pinion G on the crankshaft drove gear H. The axle of gear H was mounted on a bracket attached to the crankshaft bearing frame (and was thus sprung) and had two small-throw cranks at the end, from which rods transmitted the motion to the "Y‑shafts" mounted on top of the boiler backplate. From here rocker arms actuated the slide valves. Gear H was loose on the valve crankshaft, which was hollow. Inside it was a sliding spindle with lugs projecting through slots in the shaft. These lugs, when the spindle was pushed in, engaged in keyways in the boss of H which in turn rotated the shaft. When the spindle was pulled out (via a crank, rod and probably a treadle on the footplate), the lugs coincided with a hollow ring in the boss and H turned freely without driving the shaft. To reverse, the driver put H out of drive, worked the valve cranks through 180 degrees by means of handles on the Y‑shaft, and put H back into drive. To stop, since the engine had no brakes, he put H out of drive, waited for half a revolution of the main crank, and put it back into drive.[2] In both cases the valve sequence was reversed. There was no variable cut‑off.

We do not know the precise arrangement of the controls for operating the drive clutch, rack lowering arm, or reversing gear. The whole design, though compact and ingenious, was made awkward by being sprung; in DOWLAIS, the next rack engine, though a similar set‑up was retained, the gearing was not sprung. PERSEVERANCE'S hollow-shaft reversing clutch was particularly curious, and it is no surprise that it was replaced by a more conventional clutch in 1840.

The safety valve was apparently a weight-loaded one (like that known to have been on DOWLAIS) mounted near the back of the boiler; it discharged into the exhaust pipe. The boiler feed pump was actuated by a small rod off the crosshead. It pushed water drawn from the tender through water heaters surrounding the exhaust pipes. The two exhaust pipes passed into the chimney support box and were bent up in short swivelling blast pipes, each in its own chimney; these pipes were parallel, not nozzled. Since the feed water heaters would cause some condensation of exhaust steam, each exhaust pipe had a downward-pointing pipe at the boiler front through which the condensate could run off. These pipes being much longer than the blast pipes and being finely nozzled, there would be little loss of blast. The engine had a "casing"; this possibly meant ordinary boiler lagging, but more likely a complete overall wooden box, approximately rectangular, such as adorned the ROYAL WILLIAM on the Gloucester & Cheltenham Tramroad, to prevent horses being frightened by the machinery. Of the tender, nothing is known except that it was four wheeled, and on each axle one wheel was fixed and one loose. No doubt it looked much like those on later Dowlais engines.

PERSEVERANCE seems to have been delivered early in June 1832, probably by sea from Neath to Cardiff and perhaps by canal from there. The detailed invoice, dated 5th June, is of some interest:

|

A Locomotive Engine with 2 10½" Cylinders fitted with metallic spring pistons, Tank for Water, fitted with copper and leather pipes, cocks, Hitcher and casing as p agreemt |

£630 |

|

Machinery for ascending Dowlais Hill, consisting of Tooth wheels, pinions, bored and faced, axles turned with cranks bored and wrought iron carriages of best faggoted iron, many parts being bored turned and faced for concentric motion, fitted with brasses, bored holes for do, double nutted and fitted with stops including patterns for wheels, levers, spindles and carrgs for disengaging pinions, Engineers time designing &c |

£75 |

| Extra for 2 stacks to lower, much additional labour, copper pipes, joints turned and bored, stays, levers for lifting with winch complete | £10 |

| Tender on springs, Wheels with casehardened Naves and Rims, axles turned and fitted with steel washers, tool box with Hinges and lock | £40 |

| 2 screwjacks with screws of best thread turned and cut in lathe, wood boxes iron hoped and spanner complete | £5. 5. 0 |

| 7 spanners for engine of various sizes 2q 3lb @ 5d | £1. 4. 7 |

| 12 spare screws 2/- 2 chisels 1 point 1 drill 7/- | 9. 0 |

| 1 Hammer steel'd 2/6 Drill Brace and Dog 3/6 ½in tap 4/- | 10. 0 |

| _______ | |

| £762. 8. 7 |

There was in addition £12.15.0 for two fitters' time in assembling and testing the engine at Dowlais, plus Charles Jordan's time and expenses on the same job which Dowlais paid direct to him. Under pressure, Neath Abbey deducted the £10 extra for the swivelling stacks, and perhaps conceded a further deduction for late delivery.

Towards the end of July, PERSEVERANCE was ready to show its paces. The Hereford Times for 4th August 1832 contained this news item:

The Dowlais Iron Company's steam carriage "Powerful" lately left the Dowlais works for the bason, a distance of eleven miles, with one hundred and twenty-six tons of iron attached to it, exclusive of engine, tender, and trams, together more than two hundred tons; the Powerful returned with forty-seven empty trams, and performed the journey to and fro, within twelve hours. — This engine is considered to be the most powerful of any in the country. The very skilful engineer Mr. Gardner, anticipates his being able to perform the journey with two hundred tons of iron, exclusive of carriages; should he accomplish this, the performance will be unprecedented in the history of locomotives.

There is no other evidence for a Dowlais engine named POWERFUL, and from the similarity of the load to that mentioned in the next article, and the closeness of the dates of the two extracts, it seems likely that the reporter got the name wrong. The Cambrian on 18th August, reminding readers that the Penydarren Company's ECLIPSE had on 22nd June hauled 23 tons down the tramroad, reported:

We are now credibly informed, that the Eclipse is eclipsed by the Perseverance, got up by the Neath Abbey Iron Co, and supplied with the assistance of a Rack running parallel with the tram plates from Pennydarran to the Dowlais Works. This engine has accomplished the amazing task of conveying from the Dowlais Works to the basin aforesaid, 126¼ tons of iron, besides the weight of the engine, tender and waggons 50¾ tons, making an aggregate of 177 tons. The engine, after waiting several hours for the discharge of iron, returned to the works with her complement of empty waggons, and ascended the side of the mountain, by means of the Rack, with ease, without stopping for steam. The fact is the more remarkable from the road winding in some places excessively, so that the engine might be seen to have passed in one place two reverse arcs, one of 30½, the other 40 yards radius, at a distance of 146 yards a head of the last loaded waggon in the train; and from the first nine miles of the road from the basin having an ascent of from 1¾ to 7¼ inches in a chain [1 in 453 to 1 in 109], and the last two miles 25½ to 481/8 inches per chain [1 in 31 to 1 in 161/2], up this last part the engine works at its usual speed, but drawing its load at 2‑5ths of the speed it makes on the other parts of the way. It is supposed that the Perseverance will take down 200 tons at a time, and convey her empty trams back to the Works, when a sufficient number of carriages with springs are prepared. It is well known that the Welsh mountains supply an immence store of the corn these iron horses require to sustain them, and having so barren a surface, it is only astonishing that the natives, or some of their more knowing tenantry, did not discover before this period the possibility of sending their mineral produce to the margin of the sea for shipment by less tedious means than canals, and locks, and apply the waters that flow down the valley, in performing mechanical operations, for which they appear by nature so admirably adapted.

Thus began the first combined adhesion/rack locomotive. Though the engine was undoubtedly cumbrous compared with the elegant ECLIPSE, its magnificent train must have included about 60 trams. A contemporary account of a journey behind it follows in the next section.

In 1840‑41 the engine was evidently given a considerable rebuild, with alterations to the rack and reversing gear, a heavier frame, a single chimney folding forwards, and a new set of coupling bars attached to a central cross member on the frame. But it bore the same general appearance to the end of its days.

2: Braking by means of reversing the engine was common practice with early locomotives. It must have imposed a considerable strain on the working gear, but speeds were low.

YN BAROD ETTO

No sooner had PERSEVERANCE arrived than Dowlais was in search of a smaller, simpler engine, apparently for the internal lines at the works. On 11th August 1832 R. Jones of Birmingham tendered to supply a four-wheeler weighing 4½ tons full, similar to one he was then building for Bailey of Nantyglo, for £350. His letter was annotated by Dowlais "Too high a price". On the same day Robert Stephenson & Company wrote in reply to an enquiry, "One of your agents called here a short time ago & requested us to send you our prices for Locomotive Engines, to suit the Rail Roads of which our Engineer, who was at Penydarran, brought us the dimensions". They would defer estimating until they had consulted with Robert Stephenson himself.

Both Jones and Stephenson were too late, for on 27th July Neath Abbey had confirmed an order, which Dowlais had placed a day or two before through Charles Jordan, for "a Locomotive Engine of 2 - 8½" Cylinders to run on 4 wheels adapted for a Rail as well as Tram Road — to be ready on the 23rd of October subject to a fine of 5£ p week for all time after that period. The price for the same to be £420". Named YN BAROD ETTO ("Ever-ready") it was a very straightforward affair compared to PERSEVERANCE. The rear cylinders, 8½ by 20in, drove direct to the front axle, so it had no gearing. The four coupled wheels were designed to run on either plate or edge rail. This was achieved by fitting flanged wheels of the type required for edge rail, and making these of such dimensions that when used on plate rails they ran on the edge of their unusually thick flanges. The gauge inside the wheel flanges was 4ft 6in as usual, the edge gauge 4ft 8in; the diameter was 3ft 4in over the flanges and 2ft 10in on the edge wheel tread.

|

|

|

Since there was no rack, and there are no signs that the chimney could be lowered, YN BAROD ETTO was no doubt destined for the 4ft 4in tramroads and the intended standard gauge track inside Dowlais works. Because only ten drawings survive (all of separate parts and dated between 1st August and 4th October 1832) the overall picture of the engine is far from complete. The frame, 1⅜in thick, was a little heavier than PERSEVERANCE'S and a central cross member held the coupling bars. The boiler was probably multitubular and had a proper smokebox with a top-hung door. The twin blast pipes were slightly nozzled. The Y‑shaft was mounted on the cylinder ends, but there is no indication of how it was driven — no doubt by pinion and crank again. We have no information about the boiler mountings or the tender; there was probably a feed water heater round each exhaust pipe. The name was painted on a board on each side. The engine was shipped from Neath to Cardiff at a freight of £10 on 8th November 1832 (two weeks late), and again Charles Jordan was sent to superintend the trials — other workmen were afraid to go to Dowlais because of the cholera raging there.

Although nothing came of the approach to Stephensons in 1832, some lists of early Stephenson engines quote no.48 (in the second series) as an 0‑4‑0 named DOWLAIS, with inside cylinders 12 by 16in and 5ft wheels, supplied new to Dowlais in 1833. This is certainly wrong. Apart from the unlikelihood of such large wheels being used on a rough plateway, there is no trace whatever in the Dowlais correspondence of any contact with Stephensons after August 1832, and no trace of such an engine at Dowlais at this time. The original Stephenson evidence equally denies the existence of this engine. The two Order Books, two Description Books and the Particulars Book which cover the early 1830s provide a complete list of works numbers from 27 onwards; there is no sign at all of an engine for Dowlais, 48 being an incline winding engine built in 1833 for Netherton Colliery in Northumberland.[3] The possibility that the locomotive was built by Tayleur on behalf of Stephensons is also refuted by its absence from the Vulcan list. The answer may be that the engine was bought second-hand (and renamed) by Dowlais at some later date, most likely in the 1840s, for use on the new standard gauge railway around the works. The quoted dimensions suggest that it was of the standard four-coupled 'Planet' type. ATLAS and MILO on the Liverpool & Manchester and COMET on the Leicester & Swannington are possible originals; certainly the L&M was in the habit of selling off engines, even though young, when they were superseded by the rapid advance of locomotive technology.

Comparison of the usually accepted Stephenson list with the original Stephenson papers shows both that it is inaccurate in its numbering of engines which did exist and that it ascribes to locomotives about a dozen numbers between 39 and 59 which were really borne by non-locomotive items. Some examples are locomotives allegedly delivered new in 1833‑34 to the Groby Granite Company, Bagworth Colliery, Ibstock Brick & Tile Company, Coleorton Railway, Butterley Company and the Cromford & High Peak Railway. No doubt these places did ultimately own early Stephenson engines, but they seem to have bought them second-hand at a later date. It appears that the compiler of the list knew that these engines existed at these places, and inserted them into his list as new whereas in fact they are duplicates of earlier engines already in the list. The inclusion of the Earl of Dudley's DUDLEY as a new engine is an earlier instance of this phenomenon: as has been seen it may have been ECLIPSE in a new guise.

3: Quite a few Robert Stephenson works numbers at that time were given to non-locomotive products.

MOUNTAINEER

Returning to the Neath Abbey series, we do not know just when MOUNTAINEER was ordered, but the eleven drawings of components are dated from 9th July to 17th September 1833. It was generally similar to YN BAROD ETTO but an 0‑6‑0; as the chimney was hinged and the drawings include a profile of the tunnel, MOUNTAINEER was evidently for use on the Penydarren Tramroad, even though it had no rack for the Dowlais section. The frame was a reversion to the PERSEVERANCE size of 3in by 1 in; the wheels (of unknown pattern) were of 3ft 4in diameter. The boiler was closely similar to that of CHARLES JORDAN (illustrated later) but had 33 parallel tubes. Replacement tubes for MOUNTAINEER were pressed to 120 Ib/sq in so that working pressure was perhaps around 80 Ib/sq in; this is the only hint we have for boiler pressures at Dowlais. The cylinders were 8½in by 20in; there was apparently a feed water heater (although there are no drawings of pipework); and the single chimney was held up by a stay probably fixed to the dome. The horse power was 8½. There is a complete drawing of the tender, of typical Neath Abbey design with a tank on top and dual-purpose wheels with an edge gauge of 4ft 8½in.

MOUNTAINEER cost £450, probably excluding the tender, and was sent early in 1834 by sea to Cardiff where it met with the misfortune of being dropped into the ship's hold during unloading. Neath Abbey had to supply two new wheels and other items to repair the damage — small objects like these were sent by cart to Pont Walby at the head of Glyn Neath where a Dowlais cart picked them up. On 8th March 1834 Charles Jordan junior went to Dowlais "for putting the Mountaineer Engine in order and when complete his father will be up to start her".

DOWLAIS

A year later another rack engine was contemplated. Neath Abbey wrote to Dowlais on 19th January 1835: "Our price for a Locomotive Engine of the same power as the "Mountaineer" will be £500 ... We cannot say the cost of the machinery requisite for working on the Rack as it is a point that requires a good deal of consideration and had best be decided on by your as well as our Engineer — when the mode of doing it is fixed we will give you an estimate". The design for the rack gearing was hammered out in February, but for some reason a long delay ensued. By the autumn Dowlais was pressing for its engine; Neath Abbey replied on 29th September, "We have 10 or 12 good workmen on your Locomotive Engine — almost every part is cast and bored or forged — The fitting it together is of course more tedious and it is almost impossible to say to a week how long it will take, but we hope to have the steam up in 6 or 7 weeks — sooner if possible". It was not finished until January 1836, and even then Dowlais quibbled about the bill for the rack gear, claiming that it was the design of their own engineer and that Neath Abbey's charge of £3.3.6 for materials and labour, £24.17.3 for fitting, and £6.6.0 for Charles Jordan's time in making drawings was excessive. But the bill — a total of £604.19.1 probably including the tender — was paid, under protest.

The engine was named DOWLAIS (sometimes referred to as No.4). 28 drawings of components survive, dated between 20th June and 23rd December 1835; but an almost complete side elevation was published in Engineering for 15th November 1867. This does not show many of the controls, and omits a few other details like the diagonal stay from the boiler back to the footplate for support, and the coupling bars from cross members under the smokebox and the footplate. Most of the design was of the same type as DOWLAIS's predecessors — the front view of the smokebox, for example, was identical to that of YN BAROD ETTO — and the force pump and feed water heater followed the usual pattern. The six‑coupled wheels, for plate rail only, were 3ft 1in in diameter, the frame was 3in by 11/8in, the boiler was almost identical to MOUNTAINEER'S with 33 tubes but 5in longer, and the cylinders — at the front for a change — were 8½in by 18in. The single chimney was lowered forwards by a roller and chain winch, though this is mentioned only in the invoice, not in the drawings. The tender was practically the same as MOUNTAINEER'S, with edge/plate wheels.

|

|

|

|

DOWLAIS, Neath Abbey 1836 |

("Engineering", 15th November 1867) |

DOWLAIS is most interesting, however, for the very compact rack mechanism, which is more clearly seen in the plan than in the Engineering engraving. On the crankshaft was a pinion A which could be slid along a keyway by means of a crank and a handle that was held in a three-notched quadrant in neutral, rack or adhesion. For adhesion drive the spokes of A were engaged in the clutch of the pinion B, which was loose on the crankshaft and permanently meshed with the gear C fixed on the rear axle. When driving the rack, pinion A meshed with gear D on the rack spindle, the rack wheel E being 1ft 3½in in pitch diameter. The rack spindle was mounted on a U‑frame held at the front by bearings on the crankshaft and raised or lowered by crank and rods actuated by a 4ft lever on the footplate. The third gear on the crankshaft, F, was fixed. It was always in mesh with the gear G that was loose on the valve working shaft; G could be engaged at diametrically opposite positions by the sliding clutch H, which was held open against a spring by a pedal on the footplate. Two cranks of 21/8in throw transmitted the drive from the working shaft to the Y‑shaft with its handles, and rockers from there operated the valves. The driver reversed and braked in the same way as on PERSEVERANCE. DOWLAIS moved 8ft 9in per revolution of the crankshaft by adhesion, or 3ft 7in by rack.

After the debacle with MOUNTAINEER at Cardiff, Neath Abbey dispatched DOWLAIS on 19th January 1836 by road. William Baker, the haulier employed, was understandably fearful about conveying so large a chunk of ironmongery, and demanded £21 for the job plus expenses plus keep for his horses. The distance involved — up the Vale of Neath and over the upland road between the valleys, which reached a height of 1178ft — was 24 miles. Dowlais in turn was dubious about the cost, but Neath Abbey pointed out that the freight by sea would be at least £30 and that it might be a month before they could get the services of either of the two ships they knew of which could take a locomotive. Neath Abbey sent four men to accompany the engine. DOWLAIS was hauled along the road on its own wheels, to which were bolted specially-cast hoops with treads 6in wide to avoid rutting the surface. Presumably the journey was completed without undue disaster, for on 19th March "the Tender for your "Dowlais" Locomotive Engine is sent up by Wm Baker this day — its weight is 2 Tons and we could not get him to take it for less than 1/9 p ton p mile".

CHARLES JORDAN

The next engine was called after the Neath Abbey engineer; it boasted nameplates and was also known as No.5. It was a fairly straightforward 0‑6‑0, very like MOUNTAINEER, and had no rack, though the lowering chimney places it on the Penydarren Tramroad rather than in the Dowlais works. There are fifteen drawings of it in the collection, dated from 14th August 1837 to 13th February 1838. The wheels were probably dual-purpose, 3ft 4in in diameter; the frame was once again of 3in by 1in bar and the coupling bars started at a central cross-member; the cylinders were 8½in by 20in. There is no evidence for the tender, but we can guess it was similar to those of other Neath Abbey engines. The boiler was not unlike MOUNTAINEER'S, but had only 26 tubes that splayed out from the long semicircular flue-type firebox towards the front tubeplate. The boiler backplate was not circular, but extended upwards to a rectangular top for the easier support of the Y‑shaft. Details of the valve motion are entirely lacking, but a section of the cylinder shows that the slide valve had only a nominal steam lap (1/8in, with ports 1in long and a valve travel of 2¼in) and no exhaust lap. There was apparently no lead. Expansive working was therefore minimal, which need not surprise us as the function of valve lap was hardly understood then. The piston rings, as in the earlier engines, were of brass and in three parts, tightened by triangular wedges after the method adopted by Isaac Dodds in 1831. The chimney was raised and lowered by a chain wound on a roller at the boiler back, which the driver turned by a handle and bevel gears. A stay on the chimney gave the necessary purchase to lift the chimney from the horizontal.

Like DOWLAIS, CHARLES JORDAN was delivered by road. On 16th February 1838 a document was signed: "It is agreed between William Baker & the Neath Abbey Iron Company on behalf of Guest Lewis & Company that the latter shall pay the former for taking a 6 Wheeled Locomotive Engine to Dowlais, the same price as he received for the "Mountaineer" Engine about 4 years ago, & that he shall be paid £4.10 for the Tender. The Dowlais Company to send 4 men to accompany the Engine. W. Baker to bring back any Tools or Apparatus taken from Neath Abbey". This is odd, since MOUNTAINEER travelled by sea; perhaps they meant DOWLAIS in 1836. Hoops were again attached to the wheels for the journey, but the drawing of them is also mysterious, since their outer diameter makes them too large for the close-set wheels. It could have been managed by removing the centre wheels, but six hoops were cast. The springs seem to have suffered in the process, as a month later Dowlais was ordering replacements for CHARLES JORDAN.

JOHN WATT

The last Dowlais plateway engine was No.6, JOHN WATT, named after the Dowlais engineer who seems to have been responsible for transport matters from this time. There are eleven drawings of parts, ranging in date from 22nd November 1837 to 9th April 1838, which leave major gaps in our knowledge. The engine was something of a cross between YN BAROD ETTO and CHARLES JORDAN, being an 0‑4‑0 like the former but having a long boiler identical to the latter's. This resulted in large overhangs: 4ft at the front, 5ft 6in wheelbase, 5ft 2in at the rear. The wheels, of unknown diameter, were of edge/plate pattern. The frame was much heavier than on its predecessors, being 3in wide and 2½in thick. The cylinders were of 8½in diameter and unknown stroke. The drive was to the front wheels, and from the rear axle a pair of gears drove the valve working shaft. The driven gear was engaged by one of two clutches on either side of it, which were moved sideways by a bow frame worked by levers from the footplate. Connecting rods from cranks on the working shaft ran up beside the boiler in the usual way to oscillate the Y‑shaft, which was a copy of that on DOWLAIS. There was no rack. The tender was almost identical to MOUNTAINEER'S, with edge/plate wheels.

JOHN WATT was tested at Neath Abbey on 11th April 1838, and like PERSEVERANCE had a casing. The makers wrote on 24th April, "Your Locomotive Engine is cased and is now being painted. Chas Jordan is of opinion that he can attach pieces of wood to the springs so as to render its going up the road quite safe [apparently referring back to the trouble with CHARLES JORDAN'S springs] ... C. Jordan thinks it must go up to your works as it will not fit the tramroad from the village". This last sentence may mean that the Penydarren Company's tramroad from the canal at Merthyr was still of 3ft gauge; or more probably that it had been converted to 4ft 4in and that there was some obstacle on this section such as Bethesda Street tunnel which would not take a fixed chimney. The drawings are dumb on the question of the chimney, but most likely JOHN WATT, like YN BAROD ETTO, was destined for the internal works tramroad only. William Baker again did the transport: £23 for the engine, £4 for the tender. They left Neath Abbey on 2nd May 1838.

There was some trouble about the gauge of JOHN WATT. On 10th June 1838 Neath Abbey wrote: "Our Engineer Chas Jordan informs us that he had intended to put the last Locomotive Engine Wheels to 4f 8 guage and indeed they were actually fixed so and afterwards altered as he remembered being obliged to shorten the axles of a former engine to work on a road the same guage. He was also aware that the Tender wheels wer 1" less guage than the Engine but the tread of the wheels was wider and he trusted they would have done. We will however thank you to send the two axles of the Tender, their bearings and staples, and they shall be immediately altered and returned".

General remarks

It is regrettable that we know so little of the function of the Dowlais engines. PERSEVERANCE and DOWLAIS, as rack engines, were both certainly intended to haul iron all the way from Dowlais to Abercynon, and had plateway wheels only. MOUNTAINEER and CHARLES JORDAN were 6‑wheelers without rack drive, which would make the steep Dowlais section difficult if not impossible for them; but their lowering chimneys (and in the case of MOUNTAINEER the profiles of Plymouth tunnel on the drawings) indicates that they did run on the Penydarren Tramroad. We are not sure about their wheel type. YN BAROD ETTO and JOHN WATT, with edge/plate wheels and (apparently) non-lowering chimneys, seem to have served as yard engines only.

We do not know what prompted the Penydarren Company to order their Stephenson locomotive in 1828; but it was very likely this Penydarren engine which prompted Dowlais to order PERSEVERANCE. Josiah John Guest, the Dowlais ironmaster, was mechanically inclined, and no doubt gave his blessing to the whole series. (Anthony Hill of Plymouth was conservative and anti-mechanical, which is perhaps why Plymouth did not go in for early engines.) As has been seen, Dowlais engineers apparently provided rough specifications of the engines they wanted, and Charles Jordan of Neath Abbey translated them into actual designs which were then criticised by Dowlais. Just who were the Dowlais engineers concerned with transport is more problematical. Most of the correspondence from Neath Abbey to Dowlais, about locomotives as well as other engineering matters, is addressed to Thomas Evans, the agent or manager, who no doubt passed it on to the relevant engineer. "The very skilful engineer Mr Gardner" is mentioned in 1832, but nothing else is known of him. E.J. Hutchins, Guest's nephew, was consulted about DOWLAIS's chimney in 1836, and in the dispute over the bill for DOWLAIS Neath Abbey suggested that the matter might be decided by "your Engineer" J.U. Rastrick, the famous mechanical and civil engineer of the early Railway Age who presumably acted in a consulting capacity. Francis Trevithick claimed to have rebuilt and improved a Dowlais locomotive in 1837. In 1838 the responsible engineer was apparently John Watt, and by 1840 orders for spares were being made by Cope Pearse. Adrian Stephens, the engineer in charge of Dowlais mills and blowing engines from about 1827 to 1837, is credited by Wilkins with having the first locomotive built under his direction and named LADY CHARLOTTE (after Guest's wife); but as the name is not otherwise recorded for an engine and Lady Charlotte did not marry Guest until 1833, the statement seems highly dubious. Stephens was the inventor about 1832 of the steam whistle, applied at Dowlais to stationary boilers to indicate when the water was dangerously low. There is no evidence that he applied it to Dowlais locos (which were noisy enough not to need any other sign of their approach), but the idea was taken up and used on the Liverpool & Manchester from 1835.

There are few details of the demise of the locomotives. The last records of spare parts supplied by Neath Abbey are in 1840‑41, when several of the engines were given stronger frames and PERSEVERANCE was considerably rebuilt. An inventory of Dowlais plant taken in March 1848, by which time there were six standard gauge engines, lists only two plateway engines as surviving: YN BAROD ETTO, valued at £50, and MOUNTAINEER, valued at £60. The conversion to edge rail was clearly well under way. By 1856 all the plateway engines had gone, and eleven standard gauge locomotives reigned in their place.

Neath Abbey's technical practice in the 1830s, though undoubtedly ingenious, tended to be conservative in outlook. In their flue-type fireboxes, vertical or steeply-inclined cylinders and gear-driven valve motion, its engines conformed more to the Hackworth ideas still being applied on the Stockton & Darlington than to the burgeoning Stephenson and Bury schools which favoured separate fireboxes, horizontal cylinders and eccentrics. True, Neath Abbey did get round to adopting the multitubular boiler, and the duty of its engines was comparable to that of Hackworth's slow mineral locomotives rather than to the express passenger engines which pioneered the main developments. But Neath Abbey did not pretend to be in the forefront of locomotive design; it merely produced sturdy machines for use on awkward railways. It was, in fact, that great rarity of early days, a firm which specialised in industrial locomotives when almost all its contemporaries were involved in locomotives for public railways.

The Dowlais engines, though undeniably a vast improvement over horses as far as tractive effort and economy of operation went, nonetheless had serious drawbacks. As with every other locomotive running on cast iron rails — plate rails in particular — the damage they inflicted on the permanent way was colossal. Plates were liable to break under the ordinary 1½‑ton axle load of a waggon pulled by horse; what the maximum 3‑ton axle load of a locomotive did to them while pounding along and no doubt bouncing over the joints can be imagined. Francis Trevithick said that in 1837 when he knew the Penydarren Tramroad it was "necessary to send platelayers to jump from the waggon-trains to replace broken plates". Anthony Hill of Plymouth Works, the treasurer of the line, complained to Dowlais in July 1839 that of the 105 tons of plates (at 40 plates to the ton) required on 1st April to make the tramway good, only 56½ tons had been supplied by the three ironworks.

From 1st April to 22nd June about 1,600 more plates (40 tons) were broken, some 1,450 of which were smashed by the Dowlais engines. No plates at all had been supplied since early June, so that some loops had to be taken up to repair the main line. "The Tram Road is nearly impassable. One of the Dowlais Engines got off the road by Ynis Owen about four o'clock P.M. on Saturday last, & remained there until midday on Monday, during which time the whole traffic on the road was obstructed. Under these circumstances, it is quite in vain to attempt to keep the road open, & nothing remains for me but to apply to the Trustee of the Road, under the articles of Co‑partnership, to exert his powers & to call upon him to take means to discontinue the working of the Engines which cause the destruction of plates, & for the use of which the Tram road never was intended nor adapted". He was evidently overruled, but one can sympathise. The replacement of the Penydarren by an ordinary railway was quite inevitable; the wonder is that the cast iron plates did not, as elsewhere, give way to wrought iron ones, and that the Dowlais engines were allowed to punish them for so long.

But the plateway engines were full of character, and their memory lingered on. As late as 1888 it was recalled that they "were noisy screeching things, making a great clatter. The sound of the cogs, the asthmatic puffing, the clouds of smoke, and the sulphurous smell clinging around long after the engine had passed, are all part of Old Merthyr and its primitive era".

A summary list of the plateway locomotives may be useful:

PENYDARREN COMPANY

Gauge: 4ft 4in

|

- |

0‑4‑0G | Trevithick |

1804 |

SC |

8¾"x54" | converted to stationary engine in 1804 ? |

|

ECLIPSE |

0‑4‑0 |

R. Stephenson 14/1829 |

IC |

7"x20" | converted from 3ft gauge 0‑6‑0 in 1832 | |

| Gauge: 3ft | ||||||

|

- |

0‑6‑0 |

R. Stephenson 14/1829 |

OC |

7"x20" |

converted to 4ft 4in gauge 0‑4‑0 in 1832 |

|

DOWLAIS IRON COMPANY

Gauge: 4ft 4in

| PERSEVERANCE | 0‑6‑0G rack | Neath Abbey | 1832 | OC | 10½"x20" |

rebuilt 1840 /1, s/ s by 1848 |

|

| YN BAROD ETTO | 0‑4‑0* | Neath Abbey | 1832 | OC | 8½"x20" | s/s 1848‑56 | |

| MOUNTAINEER | 0‑6‑0 | Neath Abbey | 1834 | OC | 8½"x20" | s/s 1848‑56 | |

| No.4 | DOWLAIS | 0‑6‑0G rack | Neath Abbey | 1836 | OC | 8½"x18" | s/s by 1848 |

| No.5 | CHARLES JORDAN | 0‑6‑0 | Neath Abbey | 1838 | OC | 8½"x20" | s/s by 1848 |

| No.6 | JOHN WATT | Neath Abbey | 1838 | OC | 8½"x ? | s/s by 1848 |

* fitted with combined edge/plate wheels

G geared SC single cylinder IC/OC inside/outside cylinders

s/s scrapped or sold: disposal uncertain

|

|

Part 1 |

Part 3 |

|